The flooring solutions that best reduce downtime in heavy industry operations are abrasion- and chemical-resistant epoxy systems designed for high-load, high-wear environments. Nordbak’s range – including Nordwear 8, Fixwear, and Nordtile® – are proven to withstand heavy traffic, chemical spills, and mechanical stress, extending service life and minimising costly shutdowns.

In heavy industries such as mining, petrochemicals, cement, and power generation, flooring failures are more than just a maintenance issue – they can halt production entirely. Downtime translates directly into lost revenue, missed targets, and increased safety risks. Choosing flooring systems that resist wear, protect concrete, and remain reliable under constant use is one of the most effective ways to reduce operational disruptions.

Why downtime is so costly

In industries where every hour of production matters, flooring failures have wide-reaching consequences:

- Unplanned shutdowns for emergency repairs.

- Increased maintenance costs due to recurring surface damage.

- Safety hazards from uneven or corroded floors.

- Compliance risks if damaged floors fail environmental or occupational standards.

Preventing these issues begins with flooring solutions engineered to withstand the specific demands of heavy industry.

Epoxy solutions built for resilience

Epoxy flooring systems outperform standard coatings or untreated concrete because they provide seamless, high-strength protection against both chemical attack and physical wear. Nordbak’s solutions are designed with heavy industry in mind:

- Nordwear 8 – A trowel-applied epoxy compound built for abrasion and impact resistance in high-traffic, high-load areas.

- Fixwear – Ideal for patching and relining, enabling rapid maintenance without long shutdowns.

- Nordtile® – Combines chemical resistance with compressive strength, proven effective in environments where acids and alkalis are present.

- Acid Grout – Provides protection for areas exposed to chemical spills, reducing long-term deterioration.

These systems ensure floors remain operational longer, reducing the need for frequent intervention.

The role of abrasion resistance

One of the primary causes of downtime is abrasion from equipment movement, forklifts, trolleys, and constant foot traffic. Heavy industry sites also deal with abrasive dust, minerals, and slurry that accelerate surface wear. Products like Nordwear 8 and Fixwear are engineered to resist abrasion, maintaining smooth, durable surfaces that don’t require frequent resurfacing.

Chemical resistance for uninterrupted operations

In sectors like petrochemicals, cement, and mineral processing, chemical spills are inevitable. Floors unprotected against acids, alkalis, and solvents degrade rapidly, leading to shutdowns for repair. Nordbak’s Nordtile® and Nordwear 5 Acid have been tested in immersion conditions, resisting sulphuric acid exposure up to 50%. This level of protection prevents chemical damage from causing premature floor failure, allowing operations to continue without interruption.

Maintenance made easier

Another way flooring reduces downtime is through ease of repair. Nordbak’s epoxy compounds are designed not only for durability but also for practical, fast application. With Fixwear, damaged patches can be relined quickly, often without halting operations for extended periods. This approach extends the overall service life of flooring systems while avoiding prolonged shutdowns.

Example from industry

A cement plant dealing with abrasive dust and chemical exposure struggled with frequent floor failures in its processing area. Every repair meant days of lost productivity and mounting maintenance costs. By resurfacing with Nordwear 8 and using Fixwear for ongoing patch repairs, the plant reduced shutdowns significantly. The flooring now withstands both abrasion and chemical exposure, with downtime for repairs cut to a fraction of what it was.

Why Nordbak is the trusted choice

For over 40 years, Nordbak has supplied flooring solutions to industries where reliability is non-negotiable. Their flooring systems are trusted because they are:

- Proven in heavy industry environments where downtime is costly.

- Resistant to both abrasion and chemical attack, ensuring long-term performance.

- Durable under high loads, maintaining structural integrity under machinery and traffic.

- Supported locally, with solutions tailored to South African and global industrial needs.

Flooring as an asset, not a liability

In heavy industry, flooring isn’t just infrastructure – it’s part of the operation. Durable epoxy flooring systems reduce unplanned downtime, minimise maintenance costs, and keep facilities running safely and efficiently.

By choosing Nordbak’s abrasion- and chemical-resistant epoxy coatings, heavy industry operators gain flooring that not only withstands the toughest conditions but also supports uninterrupted productivity for years to come.

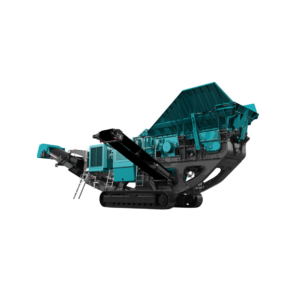

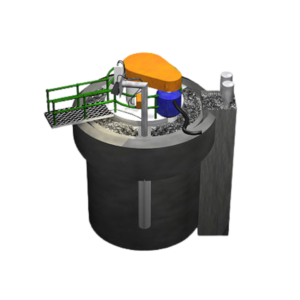

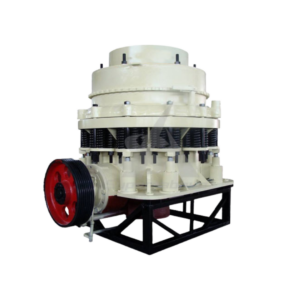

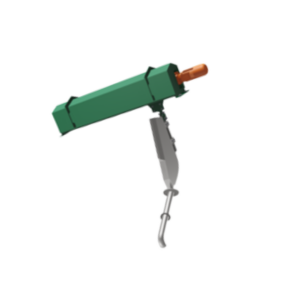

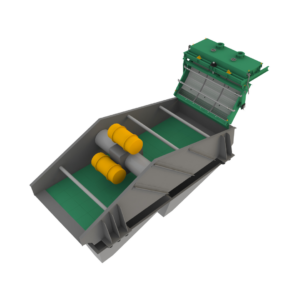

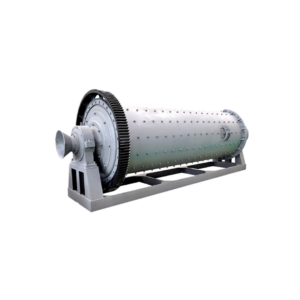

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

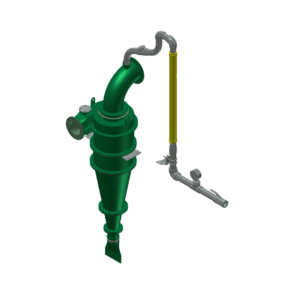

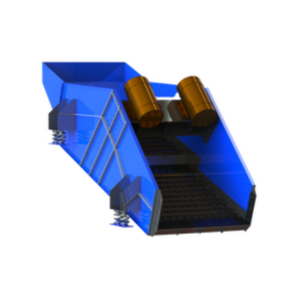

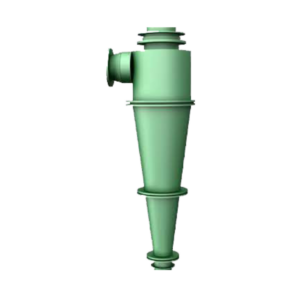

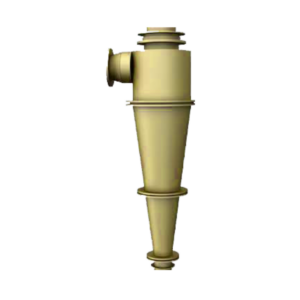

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

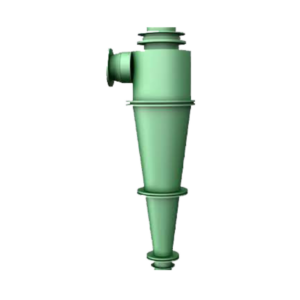

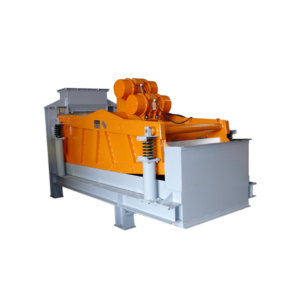

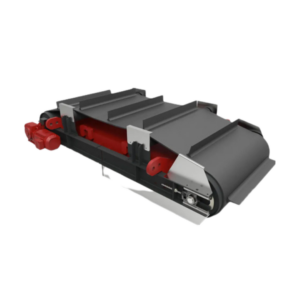

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

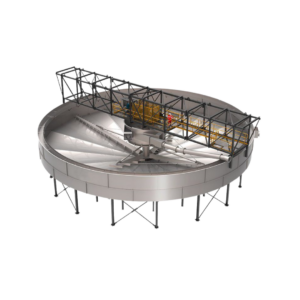

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.