The most effective floor coating for acid production environments is a high-performance acid-resistant epoxy system. Nordbak’s acid-resistant coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are specifically formulated to resist sulphuric acid, alkalis, and other aggressive chemicals commonly found in acid manufacturing.

Acid production plants present one of the harshest environments for flooring. From sulphuric acid processing to handling ammonium and sodium sulphates, floors are constantly exposed to corrosive substances that can destroy unprotected concrete. To maintain safety, compliance, and operational efficiency, facilities need floor coatings designed to withstand this chemical onslaught.

Why acid production floors are so vulnerable

Concrete on its own cannot survive in acid-heavy environments. It is porous, meaning that even small acid spills seep into the material, reacting with the lime in cement and breaking down its structure. Over time, this leads to:

- Deep pitting and crumbling of the floor.

- Weakening of structural integrity.

- Hazardous surfaces that put workers at risk.

- Escalating repair costs and downtime.

For acid production environments, unprotected concrete is simply not an option.

Acid-resistant epoxy coatings: the proven solution

Epoxy coatings provide a seamless, impermeable barrier that shields concrete from acids, alkalis, and salts. Unlike surface paints or tile systems, epoxy linings don’t leave weak points for acids to penetrate. Nordbak’s acid-resistant epoxy formulations are designed for precisely this purpose – offering long-term durability even under constant chemical exposure.

For example, Nordtile® and Nordwear 5 Acid are trowelable epoxy systems with exceptional acid resistance, proven to withstand up to 50% sulphuric acid in immersion. These products are not just resistant on the surface – they are built to hold up under prolonged and aggressive contact with acids.

Meeting both chemical and mechanical demands

In acid production, it’s not only about resisting chemicals. Floors also face heavy machinery, constant foot traffic, and regular cleaning. That’s why Nordbak’s epoxy systems combine chemical resilience with high compressive strength and abrasion resistance. Products like Fixwear and Nordwear 8 are designed to cope with both wear and corrosive attack, making them ideal for plant floors that must endure years of daily stress.

Compliance and safety considerations

Acid production facilities are subject to strict occupational health and environmental regulations. Damaged flooring poses risks of chemical seepage, environmental contamination, and workplace hazards. By installing acid-resistant epoxy flooring, plant managers can address compliance requirements proactively while improving workplace safety. Smooth, intact surfaces are easier to clean, reducing both risk and maintenance costs.

Real-world application example

Consider a sulphuric acid production plant where bund walls and surrounding floors face constant splashes and mist exposure. Within months, bare concrete begins to pit, turning the floor into a maintenance nightmare and a safety concern. After resurfacing with a Nordbak acid-resistant epoxy coating, the plant achieves a seamless, non-porous surface that resists corrosion, remains easy to clean, and meets audit requirements with confidence.

Why Nordbak is the trusted choice

Nordbak has been protecting industrial surfaces for more than 40 years, supplying acid-resistant linings and coatings to industries including mining, petrochemicals, and cement manufacturing. For acid production environments, Nordbak’s solutions stand out because they are:

- Proven in immersion conditions – withstanding direct and prolonged acid contact.

- Durable under heavy loads – combining compressive strength with abrasion resistance.

- Adaptable to different applications – suitable for floors, bund walls, tanks, and spill areas.

- Backed by local expertise – developed and manufactured in South Africa for demanding industrial use.

These coatings aren’t generic products – they are specialised systems designed and tested for the most corrosive environments.

Building long-term protection into your plant

In acid production, the choice of floor coating is not just about surface protection – it’s about long-term reliability, reduced maintenance, and workplace safety. High-performance acid-resistant epoxy systems, like those offered by Nordbak, transform vulnerable concrete floors into durable assets capable of withstanding years of exposure to the harshest chemicals.

By investing in the right flooring system, acid production plants safeguard both their infrastructure and their people. With Nordbak, you gain coatings engineered for corrosion resistance, mechanical strength, and compliance peace of mind.

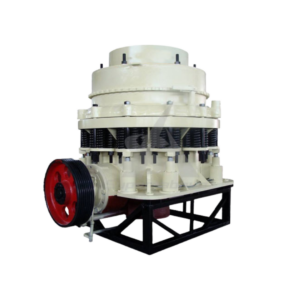

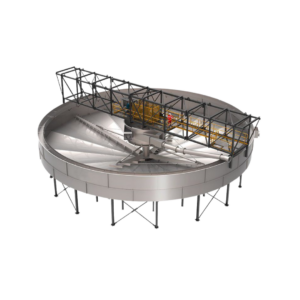

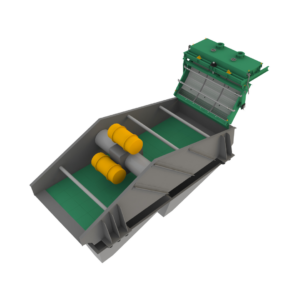

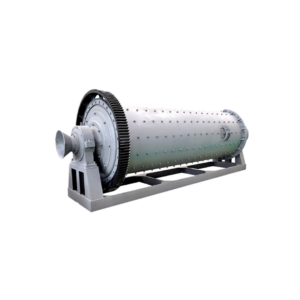

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

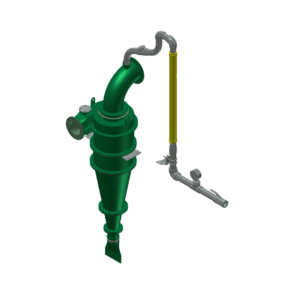

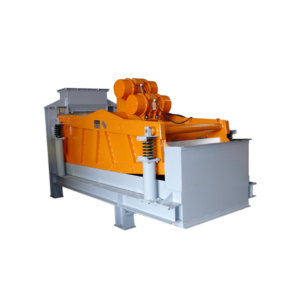

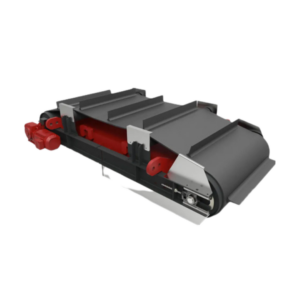

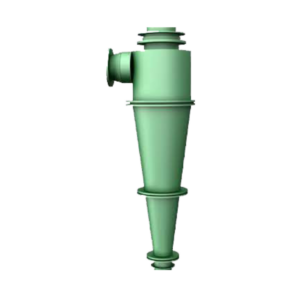

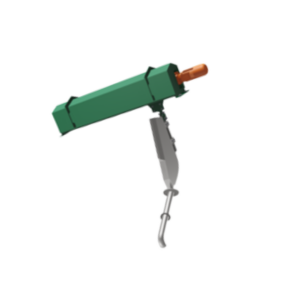

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

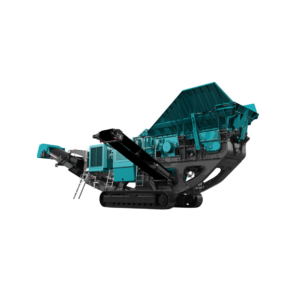

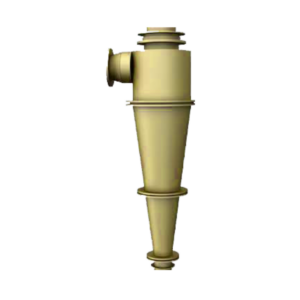

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.