The fastest curing industrial floor coatings for production plants are rapid-set epoxy and polyurethane systems designed for minimal downtime. Nordbak offers quick-curing epoxy solutions that provide chemical resistance, mechanical strength, and durability while allowing facilities to return to service faster than conventional coatings.

For production plants, every hour counts. Shutting down a line or facility for floor repairs or resurfacing can mean lost revenue and disrupted schedules. That’s why rapid-curing floor coatings are a critical solution—delivering both the protection floors need and the speed of turnaround operations demand.

Why curing time matters

Traditional epoxy systems can take several days to fully cure before they can handle heavy traffic or chemical exposure. For many production facilities, this downtime is unacceptable. The longer a floor remains out of service, the greater the impact on:

- Production schedules – missed targets due to idle equipment.

- Operational costs – labour and maintenance delays piling up.

- Customer commitments – disruptions in supply chains.

Rapid-curing floor coatings dramatically reduce this risk, offering same-day or next-day return-to-service depending on conditions.

Fast-curing epoxy systems

Rapid-set epoxy systems achieve full cure much faster than standard formulations. These products retain the strength, abrasion resistance, and chemical protection of traditional epoxy while significantly cutting downtime. Nordbak’s advanced epoxy coatings have been developed to balance quick curing with long-term durability, making them ideal for production environments where both speed and performance are essential.

In addition to quick turnaround, fast-curing epoxies still deliver critical benefits:

- Chemical resistance against acids, alkalis, and solvents.

- Abrasion and impact resistance for heavy loads and machinery.

- Seamless application preventing chemical seepage into cracks.

Polyurethane as a fast alternative

Polyurethane coatings are another option where faster cure times are needed. These systems often cure faster than traditional epoxies while offering flexibility, abrasion resistance, and chemical protection. However, epoxies generally outperform polyurethanes in high-acid environments, making Nordbak’s rapid-set epoxy systems the preferred choice for production plants where chemical resistance is critical.

Best practices for rapid-curing coatings

To ensure the best results, rapid-curing coatings must be applied with the same care as traditional systems. Best practices include:

- Thoroughly preparing the concrete substrate by cleaning and profiling.

- Applying at the recommended thickness to ensure durability.

- Monitoring environmental conditions, as humidity and temperature can affect curing times.

- Allowing full cure before returning to heavy traffic or chemical exposure—even with rapid systems.

By following these steps, facilities maximise both the speed and the lifespan of their floor coatings.

Example from industry

A food production plant faced challenges with standard epoxy flooring, as long curing times meant extended shutdowns during maintenance. By switching to a rapid-curing epoxy system, the plant was able to resurface critical floor areas overnight and resume full operations the next day. The new flooring not only cured quickly but also provided chemical resistance against cleaning agents and abrasion from constant trolley traffic.

Balancing speed and durability

Fast-curing systems are designed to reduce downtime, but they must also maintain the durability required for industrial environments. Nordbak’s solutions strike this balance, offering products that not only cure quickly but also withstand years of mechanical wear and chemical exposure.

This balance is crucial—choosing a system that cures quickly but fails within a year is more costly than investing in a coating that cures fast and lasts for decades.

Why Nordbak is trusted for fast-curing coatings

With over 40 years of experience supplying epoxy systems to mining, petrochemicals, cement, and manufacturing industries, Nordbak understands the pressures of downtime. Their rapid-curing coatings are:

- Designed for high-demand production plants where every hour counts.

- Proven in aggressive chemical and mechanical environments.

- Supported locally with tailored solutions for South African industries.

- Built for both speed and strength, ensuring long-term performance.

Fast turnaround, long-term protection

In production plants, floor coatings must deliver more than just surface protection—they must support uninterrupted operations. Fast-curing epoxy systems provide the speed facilities need without compromising on strength or chemical resistance.

With Nordbak’s rapid-curing solutions, production plants can protect their floors, reduce downtime, and keep operations running smoothly with minimal disruption.

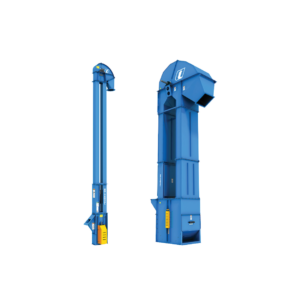

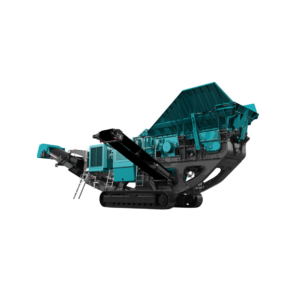

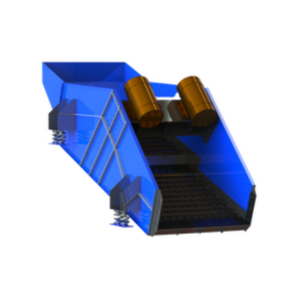

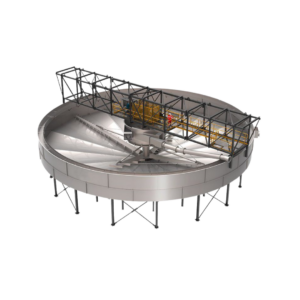

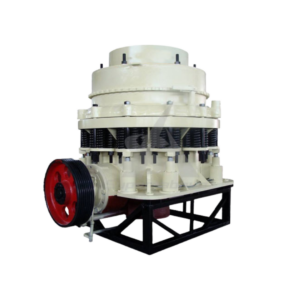

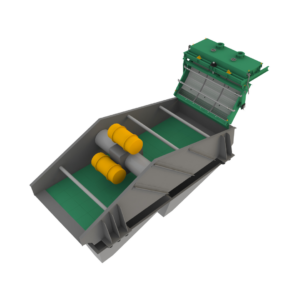

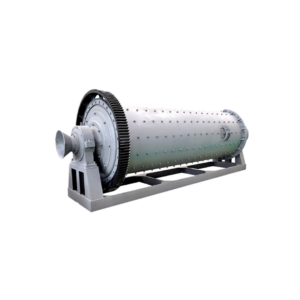

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

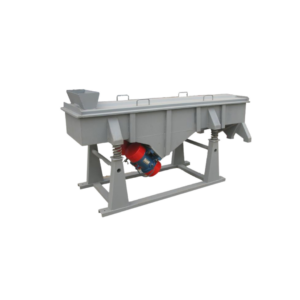

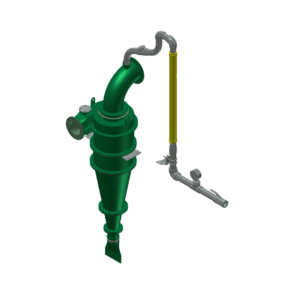

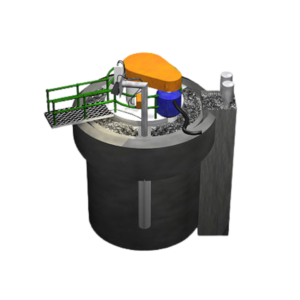

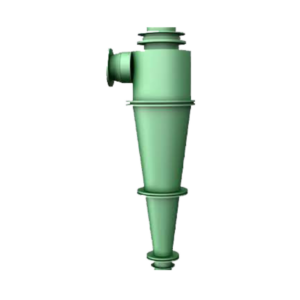

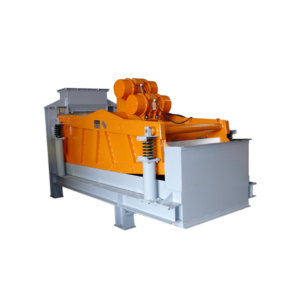

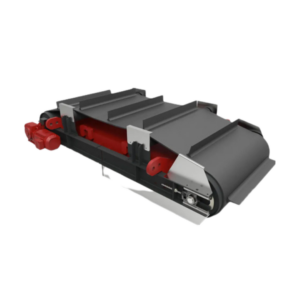

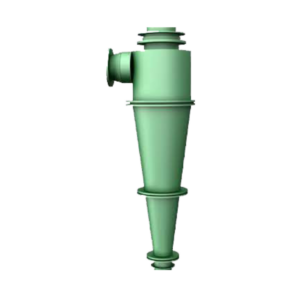

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.