The best chemical-resistant floor coating for battery storage areas is an epoxy-based acid-resistant coating, specifically designed to withstand sulphuric acid and alkaline spills. Nordbak’s range of acid-resistant coatings and grouts are proven solutions in high-risk industrial environments, offering durability, chemical protection, and long-lasting performance.

If you’re responsible for a battery storage facility – whether it’s for backup power systems, industrial plants, or large-scale energy storage – the floor beneath those batteries is one of your biggest safety and maintenance concerns. Battery acids, particularly sulphuric acid, are highly corrosive. Even a small spill can degrade concrete, weaken structural integrity, and create long-term safety hazards. This is why ordinary flooring materials aren’t enough. You need a specialised coating that not only protects against chemical attack but also stands up to the heavy wear and tear of an industrial environment.

Why standard flooring fails in battery storage areas

Concrete floors are common in industrial settings, but they are porous and vulnerable. When acid penetrates concrete, it causes pitting, cracking, and gradual structural breakdown. Tiles may resist chemicals to some degree, but the grout lines become weak points where acids seep through. Paints or standard sealants also wear quickly under repeated exposure.

The risks are clear: damaged flooring means costly repairs, potential environmental non-compliance, and hazards for workers. For facilities where safety and uptime matter, these risks aren’t acceptable.

The role of chemical-resistant epoxy coatings

Epoxy-based coatings provide a seamless, non-porous barrier that locks out corrosive agents. Unlike concrete or tile, they don’t have weak points where chemicals can penetrate. Nordbak’s acid-resistant coatings are 100% solids co-polymer systems, formulated to withstand sulphuric acid and other harsh chemicals typically present in battery applications.

One standout product for these conditions is Nordbak Acid Grout, which is used in areas exposed to dilute acid spills such as pump plinths and bund walls. For floor coatings in battery storage, Nordbak’s range of acid-resistant linings and coatings offer seamless application, durability under heavy load, and proven resistance to sulphuric acid immersion.

Proven durability in demanding environments

Nordbak has built a reputation over more than 40 years for producing acid, alkaline, and corrosion-resistant linings across industries like mining, petrochemicals, and cement manufacturing. These are some of the harshest operating environments imaginable, and the same coatings trusted there are suitable for battery storage floors.

Products such as Nordwear 5 Acid and Nordtile® have demonstrated strong performance in immersion conditions with up to 50% sulphuric acid. This makes them well suited to facilities handling batteries, where leaks or spills are an ever-present risk. By applying a Nordbak chemical-resistant coating, facility managers reduce downtime, extend floor lifespan, and ensure compliance with safety standards.

Key features to look for in a battery storage floor coating

When evaluating floor coatings for battery areas, here are the critical features that matter most:

- Chemical resistance: Ability to resist sulphuric acid, alkaline solutions, and salts.

- Seamless application: Prevents acid penetration through cracks or joints.

- High compressive strength: Withstands the weight of heavy batteries and racking systems.

- Abrasion resistance: Resists wear from equipment movement and foot traffic.

- Temperature stability: Maintains performance under fluctuating environmental conditions.

Nordbak’s coatings tick all of these boxes, combining chemical resilience with durability.

A practical example: protecting a battery room floor

Consider a backup power facility with a room housing dozens of lead-acid batteries. Over time, acid mist and occasional leaks from cells begin to damage the bare concrete floor. Small pits form, and cleaning becomes increasingly difficult. Facility managers face safety concerns and regulatory scrutiny.

By resurfacing the floor with a Nordbak acid-resistant epoxy coating, they create a seamless, easy-to-clean surface. Even if a spill occurs, the coating resists penetration, and the floor remains intact. The result? Lower maintenance costs, a safer workplace, and peace of mind that the infrastructure is protected.

Why Nordbak is the trusted choice

What sets Nordbak apart is not just the product performance but also the local expertise. With decades of experience in South Africa and beyond, Nordbak has built coatings specifically for industries where reliability isn’t optional. Every product is backed by rigorous quality control, field testing, and the ability to be tailor-made for specific applications.

Battery storage facilities demand coatings that are proven, not experimental. Nordbak’s track record across mining, petrochemicals, and industrial plants makes it a dependable partner for businesses that can’t afford downtime.

Final thoughts

If you’re asking what the best chemical-resistant floor coating for battery storage areas is, the answer is clear: a high-performance acid-resistant epoxy coating, like those offered by Nordbak. They provide the chemical protection, strength, and durability required to keep your facility safe and compliant.

Your battery room floor doesn’t just need protection – it needs the right protection. With Nordbak, you’re choosing a solution tested in the toughest industries, designed to stand up to corrosive chemicals, and supported by a team with decades of experience.

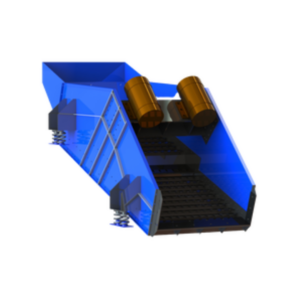

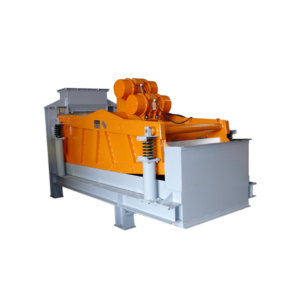

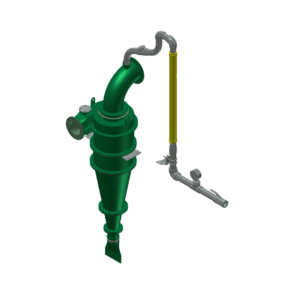

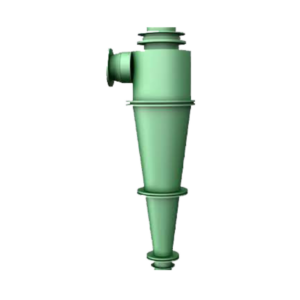

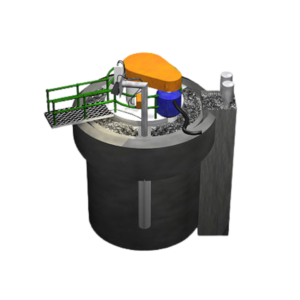

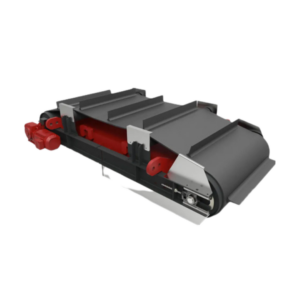

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

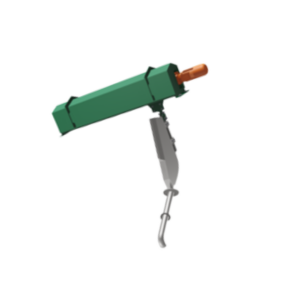

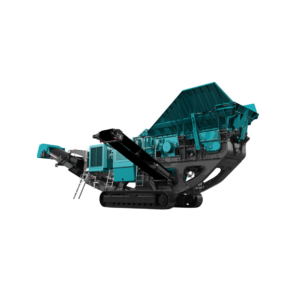

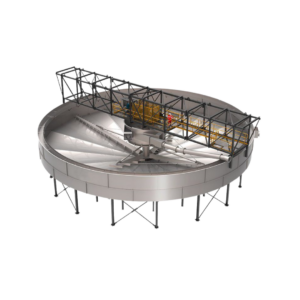

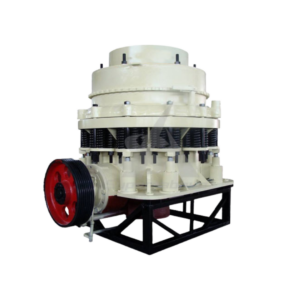

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.