The safest floor coatings for chemical spill zones are acid- and chemical-resistant epoxy systems that create a seamless, non-porous barrier against corrosive agents. Nordbak’s range of coatings – such as Nordtile®, Nordwear 5 Acid, and Acid Grout – are specifically formulated to resist acids, alkalis, and solvents, making them ideal for high-risk spill containment areas.

Chemical spill zones, whether in manufacturing plants, laboratories, or storage facilities, demand flooring that can resist sudden and frequent exposure to aggressive substances. Unlike general-purpose coatings or untreated concrete, these environments require solutions designed not only for chemical resistance but also for durability and safety.

Why spill zones need specialised coatings

Spill zones are often the first line of defence in preventing accidents from spreading. Unprotected or poorly coated floors allow chemicals to penetrate, resulting in:

- Permanent damage to the substrate.

- Increased risk of slip and trip hazards.

- Contamination issues that impact compliance.

- High repair and maintenance costs.

These risks are amplified in industries handling sulphuric acid, caustic soda, solvents, or other aggressive agents. Only coatings engineered for such exposure provide long-term protection.

Epoxy coatings: a safe and proven choice

Epoxy coatings have become the standard for spill containment areas because they provide a dense, impermeable layer that prevents chemicals from reaching the underlying concrete. Nordbak’s acid-resistant epoxy systems are specifically tested in immersion conditions, ensuring reliability even when spills are prolonged.

- Nordtile® – Offers excellent resistance to sulphuric acid immersion and is suitable for bund walls and spill zones.

- Nordwear 5 Acid – A durable, trowel-applied epoxy system designed for areas where spills combine with mechanical wear.

- Acid Grout – Provides additional strength and acid resistance in containment and spill-prone areas.

These coatings not only resist chemical damage but also provide smooth, easy-to-clean surfaces that reduce safety risks.

Key features of safe spill-zone flooring

The most effective spill-zone coatings share several critical characteristics:

- Seamless application – Prevents acids or solvents from seeping into joints or cracks.

- Chemical resistance – Withstands a wide range of aggressive substances, including sulphuric, hydrochloric, and caustic solutions.

- High compressive strength – Carries the load of equipment, containers, and heavy traffic.

- Abrasion resistance – Stands up to the movement of drums, forklifts, and trolleys.

- Ease of cleaning – Smooth finishes allow rapid spill management.

By meeting all of these requirements, Nordbak’s epoxy coatings turn vulnerable floors into safe, long-lasting assets.

Application best practices

Safe performance in spill zones depends on proper installation. Best practices include:

- Preparing the concrete substrate by removing contaminants and creating a mechanical profile for adhesion.

- Applying the coating at the recommended thickness for the specific chemical risks.

- Allowing full curing before exposing the floor to traffic or spills.

- Conducting regular inspections and timely repairs to maintain the protective barrier.

When these steps are followed, epoxy flooring systems provide reliable long-term performance even in spill-intensive environments.

Example from industry

A chemical storage facility handling sulphuric acid and solvents faced repeated floor damage in its spill containment area. Concrete pitted within months, and clean-up became increasingly difficult. After resurfacing with Nordwear 5 Acid, the spill zone gained a seamless, durable surface resistant to both chemical attack and heavy drum traffic. Years later, the coating remains intact, reducing both maintenance costs and safety risks.

Why Nordbak solutions are trusted

Nordbak has spent more than 40 years developing acid- and chemical-resistant coatings for industries including petrochemicals, mining, and manufacturing. In spill zone applications, their coatings are trusted because they are:

- Proven in aggressive chemical environments.

- Durable under load and abrasion.

- Adaptable for containment, floors, and bund walls.

- Locally manufactured and supported for South African industries.

This combination of chemical resistance and mechanical strength makes Nordbak coatings a safe and dependable choice for spill zones.

Protecting spill zones with confidence

Chemical spill zones demand flooring systems that do more than cover concrete. They must resist aggressive acids and alkalis, stand up to mechanical stress, and provide safe, easy-to-maintain surfaces.

With Nordbak’s acid- and chemical-resistant epoxy systems, facilities can protect their spill zones effectively, ensuring compliance, reducing maintenance, and keeping workers safe.

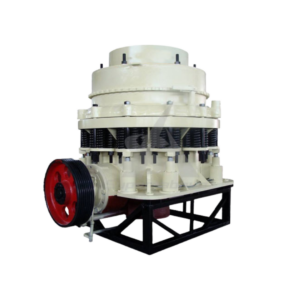

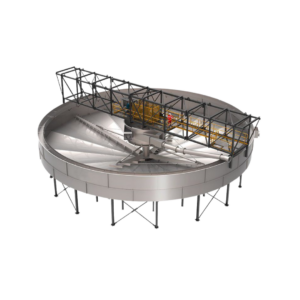

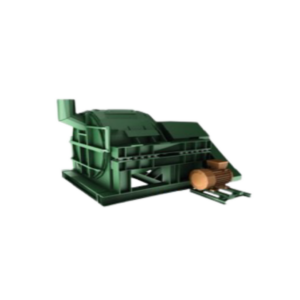

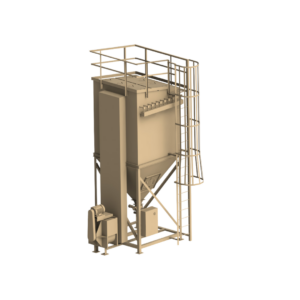

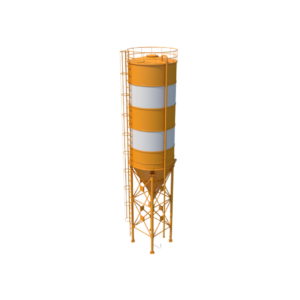

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

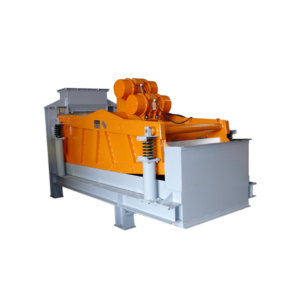

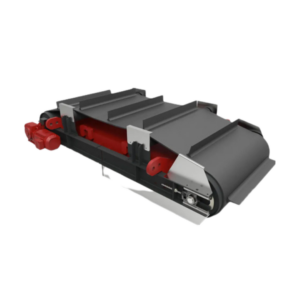

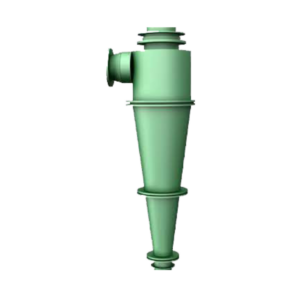

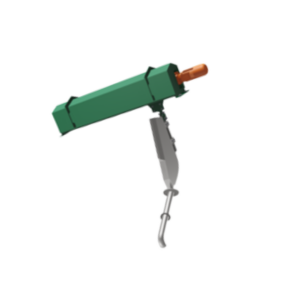

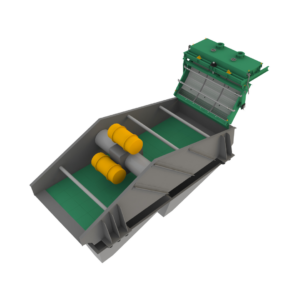

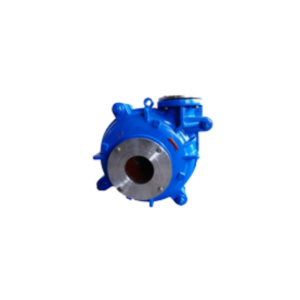

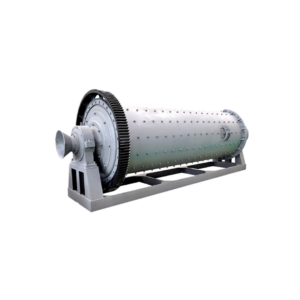

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

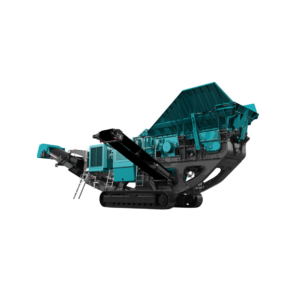

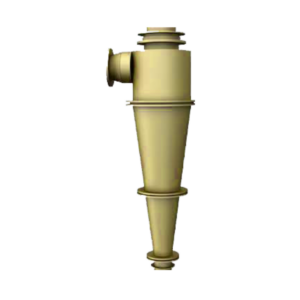

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.