The ideal epoxy coating for sewage treatment floors is a chemical- and abrasion-resistant system that protects against acids, alkalis, moisture, and biological contaminants. Nordbak’s solutions, such as Nordtile®, Nordwear 5 Acid, and Fixwear, are designed to withstand corrosive wastewater environments while ensuring long-term durability and safety.

Sewage treatment plants face some of the most aggressive operating conditions for concrete floors. Constant exposure to wastewater, cleaning chemicals, and abrasive solids quickly deteriorates untreated or poorly coated surfaces. By applying the right epoxy system, facilities can extend floor life, improve safety, and reduce costly maintenance.

Why sewage treatment floors are vulnerable

Floors in sewage plants are under attack from multiple sources:

- Acids and alkalis produced during treatment processes.

- Biological contaminants that generate corrosive by-products.

- Moisture exposure that weakens unprotected concrete.

- Abrasion from solids carried in wastewater.

- Traffic loads from trolleys, pumps, and maintenance equipment.

Without protection, floors can become pitted, slippery, and structurally weakened, creating both safety and compliance risks.

Epoxy coatings: the reliable choice

Epoxy systems are the most effective way to safeguard sewage treatment floors because they form seamless, impermeable barriers that resist chemical penetration. Nordbak’s epoxy coatings are specifically formulated for industries where chemical resistance and durability are critical.

- Nordtile® – Resists immersion in acids like sulphuric, making it well-suited for areas exposed to corrosive wastewater and cleaning agents.

- Nordwear 5 Acid – Combines strong acid resistance with abrasion strength, ideal for floors exposed to grit and suspended solids.

- Fixwear – A versatile repair compound used to patch and reinforce high-wear areas, ensuring quick maintenance without major shutdowns.

These products create floors that can handle the dual challenge of chemical attack and physical wear.

Importance of chemical resistance

Sewage treatment generates highly corrosive by-products. Hydrogen sulphide gas, for example, oxidises to sulphuric acid, which is notorious for damaging concrete. Alkalis and chlorine-based cleaning chemicals add further challenges. Nordbak’s acid-resistant epoxy systems are proven to withstand these corrosive agents, preventing deterioration and extending service life.

Abrasion resistance for long-term performance

In addition to chemical attack, abrasion from grit, sand, and other solids in wastewater is a major cause of floor failure. Standard coatings wear away quickly under this type of stress. Nordbak’s abrasion-resistant systems, such as Nordwear 8 and Fixwear, provide the compressive strength and impact resistance needed for these conditions, ensuring that the floor coating remains intact even under constant stress.

Best practices for application

To achieve the best results, sewage treatment facilities must follow proper application methods:

- Prepare the substrate by cleaning and mechanically profiling the concrete.

- Apply at sufficient thickness to ensure both chemical and abrasion resistance.

- Allow full curing before exposing the floor to wastewater or cleaning regimes.

- Inspect regularly and carry out quick repairs to prevent small issues from spreading.

By following these practices, epoxy coatings can provide decades of protection.

Example from the field

A municipal sewage treatment plant struggled with floor deterioration near settling tanks and chemical dosing areas. Bare concrete was corroding, creating unsafe and unsanitary conditions. After resurfacing with Nordwear 5 Acid, the plant achieved a seamless, durable surface resistant to both sulphuric acid and abrasion. The coating reduced maintenance costs and created a safer environment for workers.

Why Nordbak coatings are trusted

Nordbak has over 40 years of experience in providing acid- and abrasion-resistant epoxy systems for industries including mining, petrochemicals, and water treatment. Their coatings for sewage treatment applications are trusted because they:

- Resist both acids and alkalis generated in wastewater processes.

- Withstand abrasion from solids and grit.

- Provide seamless, impermeable protection against moisture and chemical ingress.

- Are backed by local expertise and field-proven durability.

This makes Nordbak a dependable partner for municipalities and private operators alike.

Building durability into wastewater infrastructure

Protecting sewage treatment floors is about more than preventing surface wear. It’s about ensuring safe, compliant, and long-lasting infrastructure. By applying Nordbak’s epoxy coatings, facilities can protect their concrete floors from chemical corrosion, abrasion, and biological attack – reducing downtime and extending service life.

With proven acid- and abrasion-resistant systems like Nordtile® and Nordwear 5 Acid, Nordbak delivers flooring solutions that keep sewage treatment plants running safely and efficiently for years to come.

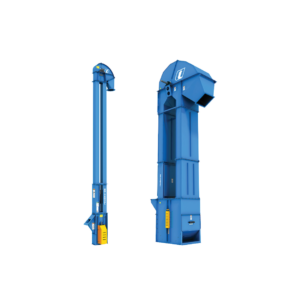

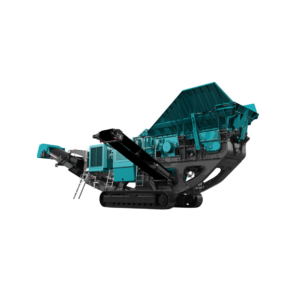

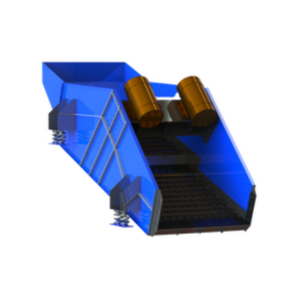

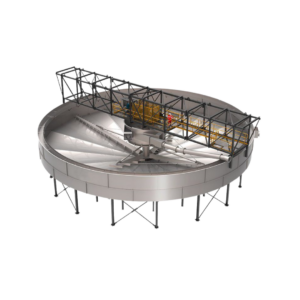

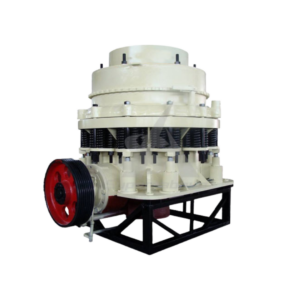

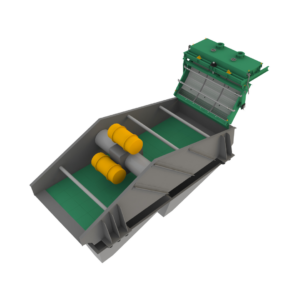

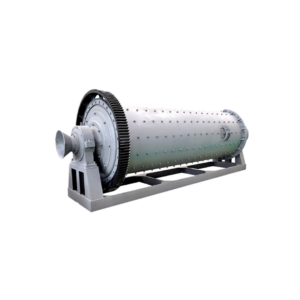

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

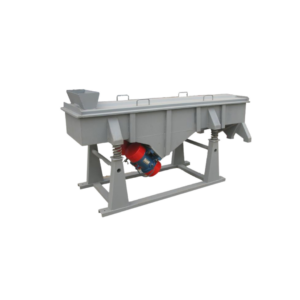

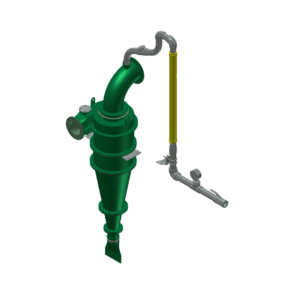

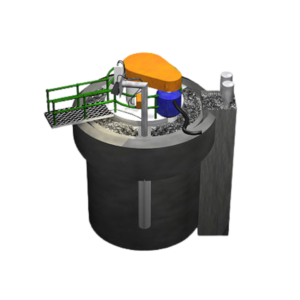

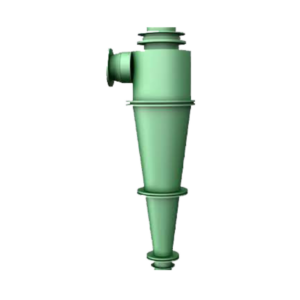

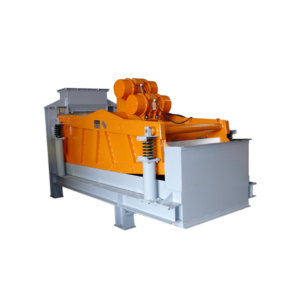

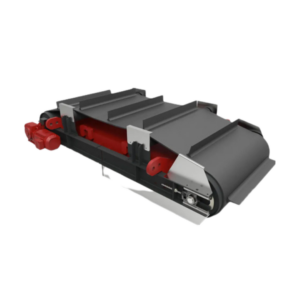

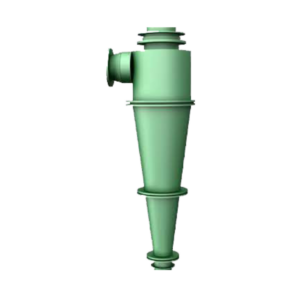

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.