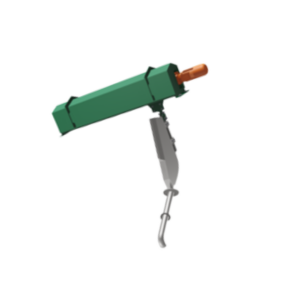

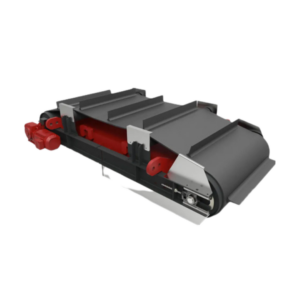

Pulley Lagging

SANS 1669-Compliant Pulley Lagging for Underground and High-Impact Environments

In tough, high-wear conveyor systems – especially underground – standard rubber just doesn’t cut it. Nordbak’s High-Impact Pulley Compound is engineered to outperform: delivering 10x the durability of rubber, 20% more grip, and full compliance with SANS 1669, ISO 340, and NES 713 standards.

Resistant to flame, smoke, slippage, and corrosion, this compound reduces belt wear, prevents slippage, and extends pulley life in the harshest environments.

Have a pulley lagging spec to meet? Connect with our team now.

High-Impact Pulley

12.5kg product number 7459-9959P

-

- Tested against and complies with Naval Engineering Standard 713 for Smoke Toxicity

- Tested against and complies with ISO 340 for Flammability

- Suitable for underground applications

- Meets the requirements of SANS 1669-2 -2016

Designed primarily for relining pulleys. At normal room temperature (25°C), curing is complete in 6 – 8 hours.

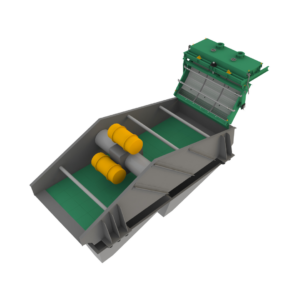

Recommended Applications

Nordbak HIGH IMPACT PULLEY is designed specifically for:

- Conveyor skirts

- Feed chutes

- Wear plates

- Slurry lines

- Pipe elbows

Wherever high wear and high impact conditions have been wearing away production profits.

Has Toxicity Index of 2

Compressive strength – 128MPa

Superior Adhesion

Has a coefficient of friction of 20% greater than rubber

Outlasts rubber in tests by at least 10 fold

The bead content repels water thus preventing slippage and increasing the life of the conveyor belts

Contact Details

Address: 193 Immelman Road, Wadeville, Germiston, 1428

Phone: +27-11-824-1640/7

Email: support@nordbak.co.za

Get in Touch with Nordbak

At Nordbak we’re committed to providing innovative solutions and excellent customer support. Let’s work together to find the right solution for your needs.

Fill out the contact form below, and our team will get back to you.

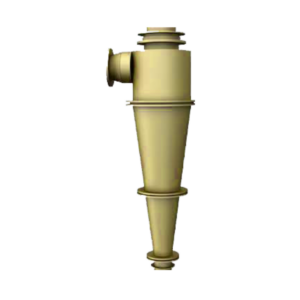

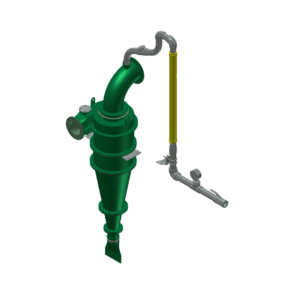

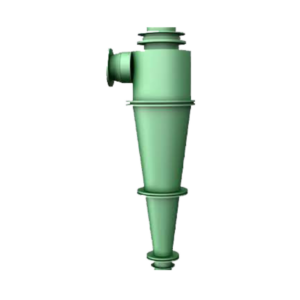

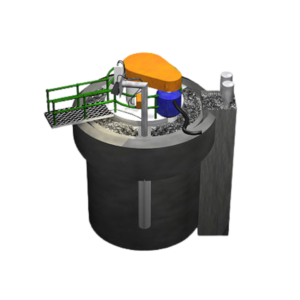

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

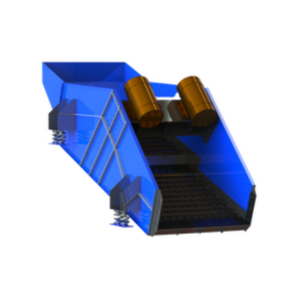

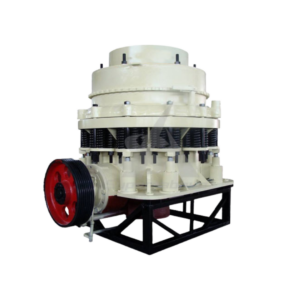

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.