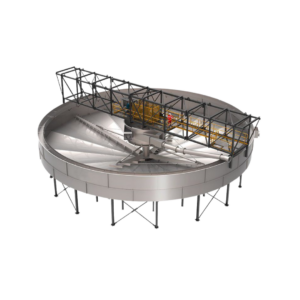

The best way to protect dam floors from chemical corrosion is to apply acid- and chemical-resistant epoxy coatings that form a seamless, impermeable barrier. Nordbak’s protective systems, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are engineered to withstand aggressive acids, alkalis, and salts commonly found in industrial water and chemical storage dams.

Dam floors, particularly in mining, chemical processing, and industrial plants, are highly vulnerable to corrosion. Whether the dam contains process water, chemical solutions, or runoff, unprotected concrete is no match for prolonged chemical exposure. Over time, floors deteriorate, leading to leakage risks, costly repairs, and environmental compliance challenges.

Why dam floors are at risk

Concrete, though strong, is naturally porous. When acids, alkalis, or salts penetrate the surface, they trigger chemical reactions that weaken the structure. In dam floors, this leads to:

- Erosion and pitting of the surface.

- Reduced load-bearing capacity.

- Leaks that compromise containment.

- Costly environmental risks if chemicals seep into soil or groundwater.

Given the scale of most dams, even minor surface damage can quickly escalate into major infrastructure problems.

Epoxy coatings: the proven solution

Epoxy-based coatings provide a seamless, impermeable shield that locks out corrosive agents. Unlike tiles or cementitious layers that leave joints or weak points, epoxy linings create a continuous barrier across the dam floor. Nordbak’s chemical-resistant epoxies are specifically formulated to withstand immersion conditions, making them ideal for dams exposed to aggressive chemicals.

- Nordtile® – Resists up to 50% sulphuric acid in immersion, suitable for heavy-duty chemical containment.

- Nordwear 5 Acid – Combines acid resistance with impact and abrasion durability, essential for high-wear areas.

- Acid Grout – Strengthens and protects floors in spill or dilute acid conditions.

These coatings provide long-lasting protection while reducing the need for frequent resurfacing.

Key steps in protecting dam floors

For dam floors to be fully protected, correct application is as important as the coating itself. Best practices include:

- Surface preparation – Cleaning and profiling the concrete to ensure strong adhesion.

- Application thickness – Applying the coating at recommended thickness for immersion environments.

- Curing time – Allowing the epoxy to fully harden before filling the dam.

- Inspection and maintenance – Regularly checking for wear or damage and repairing promptly with trowelable compounds like Fixwear.

These steps maximise both the performance and lifespan of the protective system.

Additional wear and abrasion protection

In many dams, especially those connected to mineral processing or slurry systems, abrasion is as much a threat as chemical attack. Slurries, aggregates, and suspended solids grind away at surfaces. For these conditions, Nordbak’s abrasion-resistant systems like Nordwear 8 or Fixwear provide additional reinforcement, ensuring the dam floor resists both corrosion and erosion.

Example from industry

A mining operation used a containment dam for water carrying acidic residues. Within months, the bare concrete began to pit and erode, raising concerns about leakage and compliance. The floor was resurfaced with Nordtile®, providing seamless chemical resistance and protection against sulphuric acid. Years later, the dam remains intact, with only minor patching required using Fixwear during routine maintenance.

Why Nordbak solutions are trusted

For more than 40 years, Nordbak has supplied acid- and abrasion-resistant systems to industries where chemical attack is a daily reality. In dam applications, their products are trusted because they offer:

- Proven chemical resistance in immersion conditions.

- Durability under both chemical and mechanical stress.

- Seamless application preventing hidden weak points.

- Local expertise in developing and supporting solutions for South African industry.

This combination ensures dam floors are not only protected but remain reliable over the long term.

Building long-term protection into containment systems

Protecting dam floors is about more than extending the life of concrete. It’s about safeguarding critical infrastructure, ensuring compliance, and preventing costly environmental damage. With acid- and chemical-resistant epoxy systems, dam floors can resist decades of exposure to corrosive agents.

Nordbak’s proven coatings give industries the confidence that their containment dams will perform reliably, reducing maintenance, preventing leaks, and standing strong against chemical corrosion.

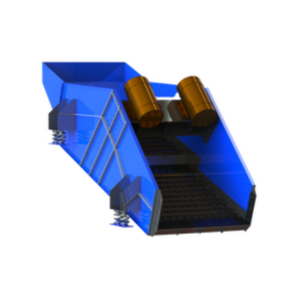

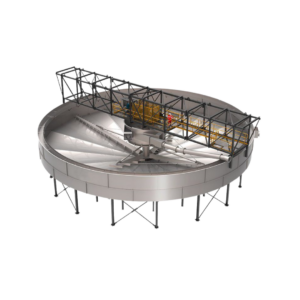

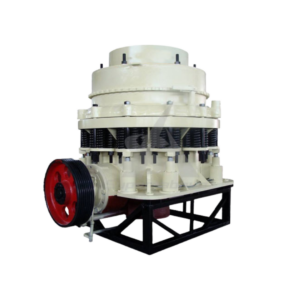

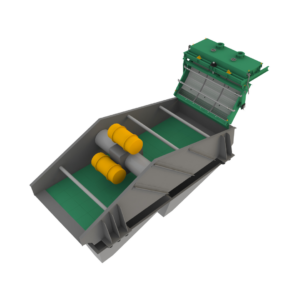

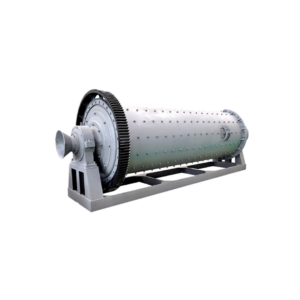

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

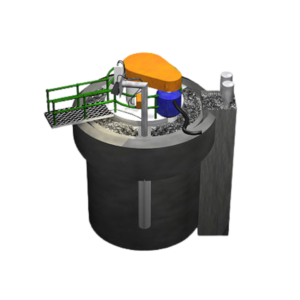

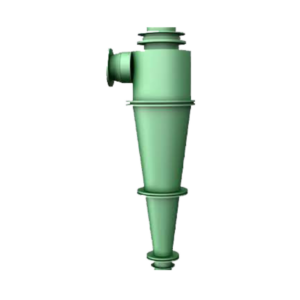

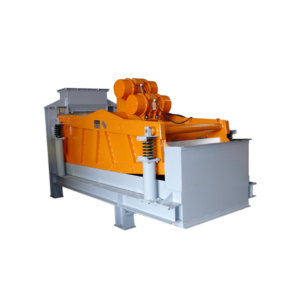

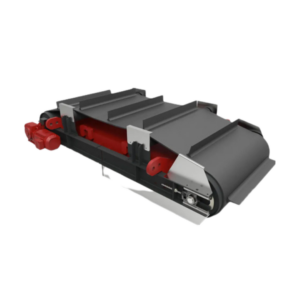

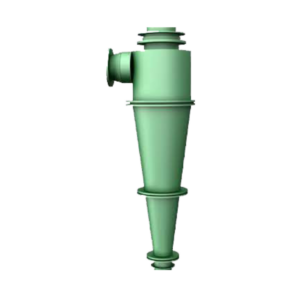

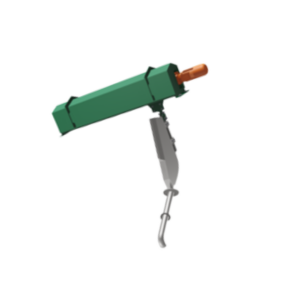

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.