Yes, epoxy floors can withstand sulfuric acid in industrial plants – provided the right acid-resistant system is chosen. Nordbak’s specialised epoxy coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are engineered to resist sulphuric acid immersion of up to 50%, making them ideal for facilities where acid exposure is unavoidable.

Sulphuric acid is one of the most widely used and most corrosive industrial chemicals. Plants involved in mining, metal processing, chemical production, and battery storage all face regular exposure to it. For floors, this means rapid deterioration if they aren’t properly protected. The right epoxy flooring system provides a durable, seamless barrier that resists chemical attack and extends the life of the underlying concrete.

Why sulphuric acid is so aggressive

Sulphuric acid reacts readily with concrete, breaking down the calcium compounds in cement and leaving the surface soft and porous. Even dilute solutions can cause:

- Deep pitting and structural weakening of concrete.

- Surface erosion that creates slip hazards.

- Staining and contamination issues that compromise compliance.

- Rapid loss of load-bearing strength.

In high-concentration areas, unprotected concrete may only survive months before serious damage occurs.

How epoxy flooring resists sulphuric acid

Unlike porous concrete or thin sealants, epoxy coatings form a dense, seamless layer that sulphuric acid cannot penetrate. Nordbak’s acid-resistant epoxy systems are specifically formulated for immersion and spillage conditions common in industrial plants.

- Nordtile® – Proven to resist up to 50% sulphuric acid immersion, suitable for bund walls and floor areas exposed to strong acids.

- Nordwear 5 Acid – A trowelable epoxy system designed for environments where both abrasion and acid attack are present.

- Acid Grout – Used to line and protect areas subject to dilute acid spills, offering compressive strength far greater than concrete.

Together, these systems provide a toolkit for protecting plant floors against even the most aggressive acid conditions.

Factors that determine performance

While epoxy systems can withstand sulphuric acid, performance depends on correct application and site conditions. Key factors include:

- Surface preparation – Concrete must be clean and mechanically profiled for proper adhesion.

- Application thickness – Thicker coatings provide better resistance to immersion and abrasion.

- Curing time – Floors must cure fully before being exposed to chemicals.

- Maintenance – Regular inspections and prompt patch repairs extend service life.

- Traffic load – Facilities with forklifts and heavy equipment require abrasion-resistant systems.

Following these best practices ensures that the epoxy system performs to its full potential.

Example from the field

In a fertiliser production plant, floors around acid mixing tanks were regularly exposed to sulphuric acid splashes. Bare concrete deteriorated quickly, creating pitted surfaces that trapped residues and raised safety concerns. After resurfacing with Nordtile®, the plant achieved a smooth, non-porous surface that resisted ongoing acid exposure. Years later, the coating remains intact, proving the long-term reliability of the system.

Why Nordbak is trusted for acid resistance

For more than 40 years, Nordbak has supplied coatings and linings to industries where sulphuric acid is a daily reality. Their products are:

- Proven in immersion conditions – tested against strong sulphuric acid.

- Durable under load – combining chemical resistance with high compressive strength.

- Versatile – suitable for floors, bund walls, and containment areas.

- Backed by local expertise – designed for South African industrial environments.

This track record means industrial plants can trust Nordbak’s epoxy solutions for safety, compliance, and long-term performance.

Protecting floors from sulphuric acid damage

Epoxy flooring is one of the few reliable ways to safeguard industrial plant floors from sulphuric acid. When the right system is applied correctly, facilities can expect years of protection against one of the most corrosive chemicals in use today.

By choosing Nordbak’s acid-resistant epoxy systems, plants can operate with confidence, knowing their floors will withstand sulphuric acid exposure while maintaining safety, compliance, and durability.

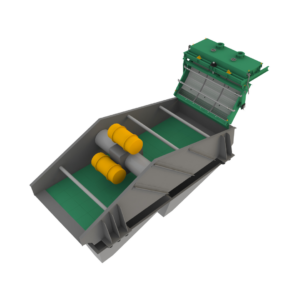

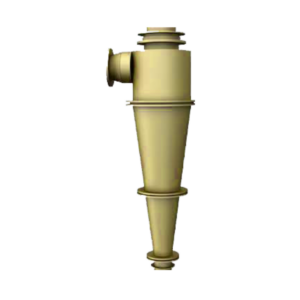

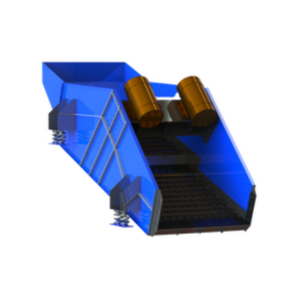

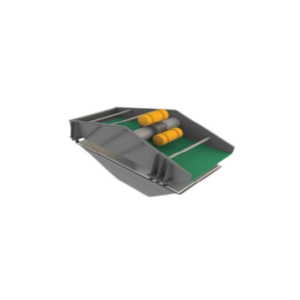

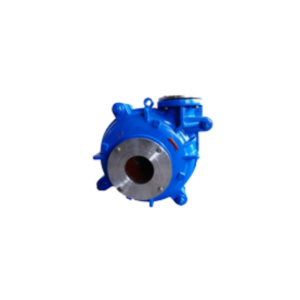

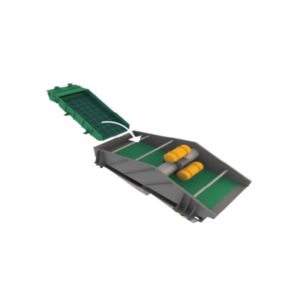

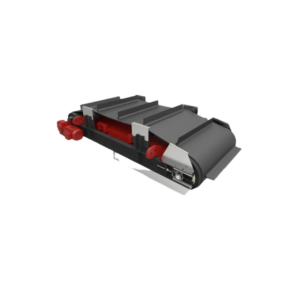

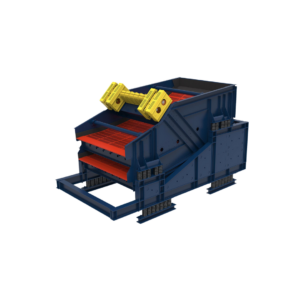

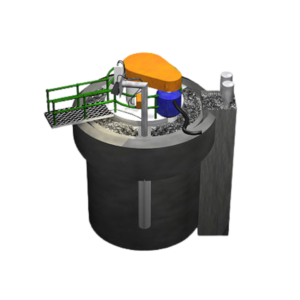

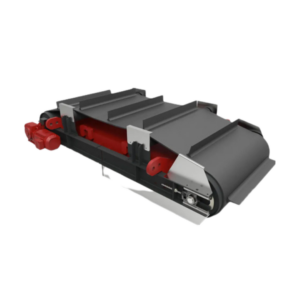

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

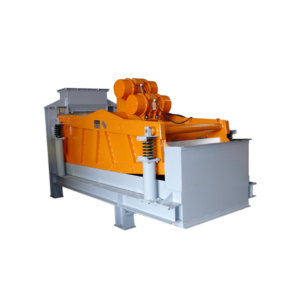

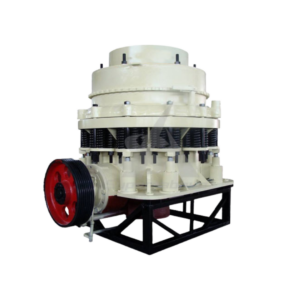

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.