Blog

Product Editorials

Nordbak Solutions – Innovation, Performance & Industry Insights

What is the safest floor coating for high-traffic warehouse areas?

The safest floor coating for high-traffic warehouse areas is a heavy-duty, abrasion-resistant epoxy system that provides both durability and slip resistance. Nordbak’s epoxy compounds, including Nordwear 8, Fixwear, and Nordtile®, are designed to withstand forklifts, pallets, and constant foot traffic while ensuring worker safety and long-term floor performance.

Warehouses are the beating heart of logistics and supply chains. But their floors endure relentless stress: forklifts running day and night, heavy racks and pallets weighing down surfaces, and constant movement of people and equipment. In such environments, safety and durability must go hand in hand. A weak or unsafe floor isn’t just inconvenient – it’s a liability.

Why warehouse floors fail

Even well-built concrete floors deteriorate quickly under warehouse conditions if left unprotected. The main threats include:

- Abrasion from forklifts, pallet jacks, and trolleys.

- Impact damage from dropped goods and machinery movement.

- Surface dusting that makes floors slippery and unsafe.

- Cracking and spalling that lead to uneven surfaces and tripping hazards.

These issues not only increase maintenance costs but also compromise worker safety and efficiency.

Epoxy coatings: a warehouse essential

Epoxy floor coatings are widely recognised as the best solution for high-traffic warehouses because they form seamless, durable surfaces that resist wear and provide a safe working environment. Nordbak’s epoxy systems are engineered to handle both heavy mechanical stress and safety requirements.

- Nordwear 8 – A tough, abrasion-resistant epoxy designed for areas under heavy traffic and load.

- Fixwear – A versatile wear compound for patching and relining damaged areas without long shutdowns.

- Nordtile® – Provides chemical resistance as well as compressive strength, ideal for warehouses that store or handle corrosive goods.

Together, these coatings provide not just durability but a safer, cleaner surface for warehouse teams.

Safety as a priority

A safe warehouse floor is more than just strong – it must also reduce the risk of slips, trips, and falls. Epoxy coatings help achieve this by:

- Creating smooth, dust-free surfaces that improve visibility and cleanliness.

- Offering non-slip finishes that reduce the risk of accidents, even when floors are wet.

- Maintaining flat and level floors that are safer for forklift operations.

By addressing both structural durability and worker safety, epoxy coatings create a safer operational environment.

Best practices for application

For coatings to perform as intended in warehouses, proper application is critical:

- Surface preparation – Concrete must be cleaned and mechanically profiled to ensure adhesion.

- Thickness of coating – Floors in high-traffic zones require thicker applications for maximum abrasion resistance.

- Curing time – Allowing coatings to fully cure ensures they can handle immediate forklift and trolley loads.

- Ongoing maintenance – Regular inspection and quick patching with compounds like Fixwear keeps floors safe and reliable.

Following these steps ensures that coatings deliver both safety and durability.

Example from the field

A large distribution warehouse experienced constant floor deterioration under forklift traffic, creating cracks and uneven surfaces that posed risks to workers and slowed operations. After resurfacing with Nordwear 8, the facility gained a seamless, slip-resistant surface that handled the heavy loads with ease. Safety improved significantly, and the warehouse reduced both downtime and repair costs.

Why Nordbak coatings are trusted in warehouses

With more than 40 years of experience in developing abrasion- and impact-resistant epoxy systems, Nordbak is trusted across industries that demand reliability. For warehouses, their coatings stand out because they:

- Withstand constant heavy traffic without breaking down.

- Resist abrasion and impact from forklifts, pallets, and equipment.

- Improve safety with slip-resistant finishes and dust-free surfaces.

- Enable quick maintenance with patch solutions that reduce downtime.

This combination of durability and safety is why Nordbak is the preferred choice for warehouse flooring.

Building safety and efficiency into warehouse operations

Warehouse floors are more than just surfaces – they’re the foundation of safe and efficient operations. By choosing abrasion-resistant epoxy systems, facilities ensure that their floors can handle the toughest traffic while protecting workers from accidents.

With Nordbak’s proven flooring solutions, warehouses gain durable, safe, and low-maintenance floors that keep operations moving smoothly and securely.

What epoxy coating is ideal for sewage treatment floors?

The ideal epoxy coating for sewage treatment floors is a chemical- and abrasion-resistant system that protects against acids, alkalis, moisture, and biological contaminants. Nordbak’s solutions, such as Nordtile®, Nordwear 5 Acid, and Fixwear, are designed to withstand corrosive wastewater environments while ensuring long-term durability and safety.

Sewage treatment plants face some of the most aggressive operating conditions for concrete floors. Constant exposure to wastewater, cleaning chemicals, and abrasive solids quickly deteriorates untreated or poorly coated surfaces. By applying the right epoxy system, facilities can extend floor life, improve safety, and reduce costly maintenance.

Why sewage treatment floors are vulnerable

Floors in sewage plants are under attack from multiple sources:

- Acids and alkalis produced during treatment processes.

- Biological contaminants that generate corrosive by-products.

- Moisture exposure that weakens unprotected concrete.

- Abrasion from solids carried in wastewater.

- Traffic loads from trolleys, pumps, and maintenance equipment.

Without protection, floors can become pitted, slippery, and structurally weakened, creating both safety and compliance risks.

Epoxy coatings: the reliable choice

Epoxy systems are the most effective way to safeguard sewage treatment floors because they form seamless, impermeable barriers that resist chemical penetration. Nordbak’s epoxy coatings are specifically formulated for industries where chemical resistance and durability are critical.

- Nordtile® – Resists immersion in acids like sulphuric, making it well-suited for areas exposed to corrosive wastewater and cleaning agents.

- Nordwear 5 Acid – Combines strong acid resistance with abrasion strength, ideal for floors exposed to grit and suspended solids.

- Fixwear – A versatile repair compound used to patch and reinforce high-wear areas, ensuring quick maintenance without major shutdowns.

These products create floors that can handle the dual challenge of chemical attack and physical wear.

Importance of chemical resistance

Sewage treatment generates highly corrosive by-products. Hydrogen sulphide gas, for example, oxidises to sulphuric acid, which is notorious for damaging concrete. Alkalis and chlorine-based cleaning chemicals add further challenges. Nordbak’s acid-resistant epoxy systems are proven to withstand these corrosive agents, preventing deterioration and extending service life.

Abrasion resistance for long-term performance

In addition to chemical attack, abrasion from grit, sand, and other solids in wastewater is a major cause of floor failure. Standard coatings wear away quickly under this type of stress. Nordbak’s abrasion-resistant systems, such as Nordwear 8 and Fixwear, provide the compressive strength and impact resistance needed for these conditions, ensuring that the floor coating remains intact even under constant stress.

Best practices for application

To achieve the best results, sewage treatment facilities must follow proper application methods:

- Prepare the substrate by cleaning and mechanically profiling the concrete.

- Apply at sufficient thickness to ensure both chemical and abrasion resistance.

- Allow full curing before exposing the floor to wastewater or cleaning regimes.

- Inspect regularly and carry out quick repairs to prevent small issues from spreading.

By following these practices, epoxy coatings can provide decades of protection.

Example from the field

A municipal sewage treatment plant struggled with floor deterioration near settling tanks and chemical dosing areas. Bare concrete was corroding, creating unsafe and unsanitary conditions. After resurfacing with Nordwear 5 Acid, the plant achieved a seamless, durable surface resistant to both sulphuric acid and abrasion. The coating reduced maintenance costs and created a safer environment for workers.

Why Nordbak coatings are trusted

Nordbak has over 40 years of experience in providing acid- and abrasion-resistant epoxy systems for industries including mining, petrochemicals, and water treatment. Their coatings for sewage treatment applications are trusted because they:

- Resist both acids and alkalis generated in wastewater processes.

- Withstand abrasion from solids and grit.

- Provide seamless, impermeable protection against moisture and chemical ingress.

- Are backed by local expertise and field-proven durability.

This makes Nordbak a dependable partner for municipalities and private operators alike.

Building durability into wastewater infrastructure

Protecting sewage treatment floors is about more than preventing surface wear. It’s about ensuring safe, compliant, and long-lasting infrastructure. By applying Nordbak’s epoxy coatings, facilities can protect their concrete floors from chemical corrosion, abrasion, and biological attack – reducing downtime and extending service life.

With proven acid- and abrasion-resistant systems like Nordtile® and Nordwear 5 Acid, Nordbak delivers flooring solutions that keep sewage treatment plants running safely and efficiently for years to come.

How to protect dam floors from chemical corrosion?

The best way to protect dam floors from chemical corrosion is to apply acid- and chemical-resistant epoxy coatings that form a seamless, impermeable barrier. Nordbak’s protective systems, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are engineered to withstand aggressive acids, alkalis, and salts commonly found in industrial water and chemical storage dams.

Dam floors, particularly in mining, chemical processing, and industrial plants, are highly vulnerable to corrosion. Whether the dam contains process water, chemical solutions, or runoff, unprotected concrete is no match for prolonged chemical exposure. Over time, floors deteriorate, leading to leakage risks, costly repairs, and environmental compliance challenges.

Why dam floors are at risk

Concrete, though strong, is naturally porous. When acids, alkalis, or salts penetrate the surface, they trigger chemical reactions that weaken the structure. In dam floors, this leads to:

- Erosion and pitting of the surface.

- Reduced load-bearing capacity.

- Leaks that compromise containment.

- Costly environmental risks if chemicals seep into soil or groundwater.

Given the scale of most dams, even minor surface damage can quickly escalate into major infrastructure problems.

Epoxy coatings: the proven solution

Epoxy-based coatings provide a seamless, impermeable shield that locks out corrosive agents. Unlike tiles or cementitious layers that leave joints or weak points, epoxy linings create a continuous barrier across the dam floor. Nordbak’s chemical-resistant epoxies are specifically formulated to withstand immersion conditions, making them ideal for dams exposed to aggressive chemicals.

- Nordtile® – Resists up to 50% sulphuric acid in immersion, suitable for heavy-duty chemical containment.

- Nordwear 5 Acid – Combines acid resistance with impact and abrasion durability, essential for high-wear areas.

- Acid Grout – Strengthens and protects floors in spill or dilute acid conditions.

These coatings provide long-lasting protection while reducing the need for frequent resurfacing.

Key steps in protecting dam floors

For dam floors to be fully protected, correct application is as important as the coating itself. Best practices include:

- Surface preparation – Cleaning and profiling the concrete to ensure strong adhesion.

- Application thickness – Applying the coating at recommended thickness for immersion environments.

- Curing time – Allowing the epoxy to fully harden before filling the dam.

- Inspection and maintenance – Regularly checking for wear or damage and repairing promptly with trowelable compounds like Fixwear.

These steps maximise both the performance and lifespan of the protective system.

Additional wear and abrasion protection

In many dams, especially those connected to mineral processing or slurry systems, abrasion is as much a threat as chemical attack. Slurries, aggregates, and suspended solids grind away at surfaces. For these conditions, Nordbak’s abrasion-resistant systems like Nordwear 8 or Fixwear provide additional reinforcement, ensuring the dam floor resists both corrosion and erosion.

Example from industry

A mining operation used a containment dam for water carrying acidic residues. Within months, the bare concrete began to pit and erode, raising concerns about leakage and compliance. The floor was resurfaced with Nordtile®, providing seamless chemical resistance and protection against sulphuric acid. Years later, the dam remains intact, with only minor patching required using Fixwear during routine maintenance.

Why Nordbak solutions are trusted

For more than 40 years, Nordbak has supplied acid- and abrasion-resistant systems to industries where chemical attack is a daily reality. In dam applications, their products are trusted because they offer:

- Proven chemical resistance in immersion conditions.

- Durability under both chemical and mechanical stress.

- Seamless application preventing hidden weak points.

- Local expertise in developing and supporting solutions for South African industry.

This combination ensures dam floors are not only protected but remain reliable over the long term.

Building long-term protection into containment systems

Protecting dam floors is about more than extending the life of concrete. It’s about safeguarding critical infrastructure, ensuring compliance, and preventing costly environmental damage. With acid- and chemical-resistant epoxy systems, dam floors can resist decades of exposure to corrosive agents.

Nordbak’s proven coatings give industries the confidence that their containment dams will perform reliably, reducing maintenance, preventing leaks, and standing strong against chemical corrosion.

What is the fastest curing industrial floor coating for production plants?

The fastest curing industrial floor coatings for production plants are rapid-set epoxy and polyurethane systems designed for minimal downtime. Nordbak offers quick-curing epoxy solutions that provide chemical resistance, mechanical strength, and durability while allowing facilities to return to service faster than conventional coatings.

For production plants, every hour counts. Shutting down a line or facility for floor repairs or resurfacing can mean lost revenue and disrupted schedules. That’s why rapid-curing floor coatings are a critical solution—delivering both the protection floors need and the speed of turnaround operations demand.

Why curing time matters

Traditional epoxy systems can take several days to fully cure before they can handle heavy traffic or chemical exposure. For many production facilities, this downtime is unacceptable. The longer a floor remains out of service, the greater the impact on:

- Production schedules – missed targets due to idle equipment.

- Operational costs – labour and maintenance delays piling up.

- Customer commitments – disruptions in supply chains.

Rapid-curing floor coatings dramatically reduce this risk, offering same-day or next-day return-to-service depending on conditions.

Fast-curing epoxy systems

Rapid-set epoxy systems achieve full cure much faster than standard formulations. These products retain the strength, abrasion resistance, and chemical protection of traditional epoxy while significantly cutting downtime. Nordbak’s advanced epoxy coatings have been developed to balance quick curing with long-term durability, making them ideal for production environments where both speed and performance are essential.

In addition to quick turnaround, fast-curing epoxies still deliver critical benefits:

- Chemical resistance against acids, alkalis, and solvents.

- Abrasion and impact resistance for heavy loads and machinery.

- Seamless application preventing chemical seepage into cracks.

Polyurethane as a fast alternative

Polyurethane coatings are another option where faster cure times are needed. These systems often cure faster than traditional epoxies while offering flexibility, abrasion resistance, and chemical protection. However, epoxies generally outperform polyurethanes in high-acid environments, making Nordbak’s rapid-set epoxy systems the preferred choice for production plants where chemical resistance is critical.

Best practices for rapid-curing coatings

To ensure the best results, rapid-curing coatings must be applied with the same care as traditional systems. Best practices include:

- Thoroughly preparing the concrete substrate by cleaning and profiling.

- Applying at the recommended thickness to ensure durability.

- Monitoring environmental conditions, as humidity and temperature can affect curing times.

- Allowing full cure before returning to heavy traffic or chemical exposure—even with rapid systems.

By following these steps, facilities maximise both the speed and the lifespan of their floor coatings.

Example from industry

A food production plant faced challenges with standard epoxy flooring, as long curing times meant extended shutdowns during maintenance. By switching to a rapid-curing epoxy system, the plant was able to resurface critical floor areas overnight and resume full operations the next day. The new flooring not only cured quickly but also provided chemical resistance against cleaning agents and abrasion from constant trolley traffic.

Balancing speed and durability

Fast-curing systems are designed to reduce downtime, but they must also maintain the durability required for industrial environments. Nordbak’s solutions strike this balance, offering products that not only cure quickly but also withstand years of mechanical wear and chemical exposure.

This balance is crucial—choosing a system that cures quickly but fails within a year is more costly than investing in a coating that cures fast and lasts for decades.

Why Nordbak is trusted for fast-curing coatings

With over 40 years of experience supplying epoxy systems to mining, petrochemicals, cement, and manufacturing industries, Nordbak understands the pressures of downtime. Their rapid-curing coatings are:

- Designed for high-demand production plants where every hour counts.

- Proven in aggressive chemical and mechanical environments.

- Supported locally with tailored solutions for South African industries.

- Built for both speed and strength, ensuring long-term performance.

Fast turnaround, long-term protection

In production plants, floor coatings must deliver more than just surface protection—they must support uninterrupted operations. Fast-curing epoxy systems provide the speed facilities need without compromising on strength or chemical resistance.

With Nordbak’s rapid-curing solutions, production plants can protect their floors, reduce downtime, and keep operations running smoothly with minimal disruption.

Which flooring solutions reduce downtime in heavy industry operations?

The flooring solutions that best reduce downtime in heavy industry operations are abrasion- and chemical-resistant epoxy systems designed for high-load, high-wear environments. Nordbak’s range – including Nordwear 8, Fixwear, and Nordtile® – are proven to withstand heavy traffic, chemical spills, and mechanical stress, extending service life and minimising costly shutdowns.

In heavy industries such as mining, petrochemicals, cement, and power generation, flooring failures are more than just a maintenance issue – they can halt production entirely. Downtime translates directly into lost revenue, missed targets, and increased safety risks. Choosing flooring systems that resist wear, protect concrete, and remain reliable under constant use is one of the most effective ways to reduce operational disruptions.

Why downtime is so costly

In industries where every hour of production matters, flooring failures have wide-reaching consequences:

- Unplanned shutdowns for emergency repairs.

- Increased maintenance costs due to recurring surface damage.

- Safety hazards from uneven or corroded floors.

- Compliance risks if damaged floors fail environmental or occupational standards.

Preventing these issues begins with flooring solutions engineered to withstand the specific demands of heavy industry.

Epoxy solutions built for resilience

Epoxy flooring systems outperform standard coatings or untreated concrete because they provide seamless, high-strength protection against both chemical attack and physical wear. Nordbak’s solutions are designed with heavy industry in mind:

- Nordwear 8 – A trowel-applied epoxy compound built for abrasion and impact resistance in high-traffic, high-load areas.

- Fixwear – Ideal for patching and relining, enabling rapid maintenance without long shutdowns.

- Nordtile® – Combines chemical resistance with compressive strength, proven effective in environments where acids and alkalis are present.

- Acid Grout – Provides protection for areas exposed to chemical spills, reducing long-term deterioration.

These systems ensure floors remain operational longer, reducing the need for frequent intervention.

The role of abrasion resistance

One of the primary causes of downtime is abrasion from equipment movement, forklifts, trolleys, and constant foot traffic. Heavy industry sites also deal with abrasive dust, minerals, and slurry that accelerate surface wear. Products like Nordwear 8 and Fixwear are engineered to resist abrasion, maintaining smooth, durable surfaces that don’t require frequent resurfacing.

Chemical resistance for uninterrupted operations

In sectors like petrochemicals, cement, and mineral processing, chemical spills are inevitable. Floors unprotected against acids, alkalis, and solvents degrade rapidly, leading to shutdowns for repair. Nordbak’s Nordtile® and Nordwear 5 Acid have been tested in immersion conditions, resisting sulphuric acid exposure up to 50%. This level of protection prevents chemical damage from causing premature floor failure, allowing operations to continue without interruption.

Maintenance made easier

Another way flooring reduces downtime is through ease of repair. Nordbak’s epoxy compounds are designed not only for durability but also for practical, fast application. With Fixwear, damaged patches can be relined quickly, often without halting operations for extended periods. This approach extends the overall service life of flooring systems while avoiding prolonged shutdowns.

Example from industry

A cement plant dealing with abrasive dust and chemical exposure struggled with frequent floor failures in its processing area. Every repair meant days of lost productivity and mounting maintenance costs. By resurfacing with Nordwear 8 and using Fixwear for ongoing patch repairs, the plant reduced shutdowns significantly. The flooring now withstands both abrasion and chemical exposure, with downtime for repairs cut to a fraction of what it was.

Why Nordbak is the trusted choice

For over 40 years, Nordbak has supplied flooring solutions to industries where reliability is non-negotiable. Their flooring systems are trusted because they are:

- Proven in heavy industry environments where downtime is costly.

- Resistant to both abrasion and chemical attack, ensuring long-term performance.

- Durable under high loads, maintaining structural integrity under machinery and traffic.

- Supported locally, with solutions tailored to South African and global industrial needs.

Flooring as an asset, not a liability

In heavy industry, flooring isn’t just infrastructure – it’s part of the operation. Durable epoxy flooring systems reduce unplanned downtime, minimise maintenance costs, and keep facilities running safely and efficiently.

By choosing Nordbak’s abrasion- and chemical-resistant epoxy coatings, heavy industry operators gain flooring that not only withstands the toughest conditions but also supports uninterrupted productivity for years to come.

What floor coatings are safe for use in chemical spill zones?

The safest floor coatings for chemical spill zones are acid- and chemical-resistant epoxy systems that create a seamless, non-porous barrier against corrosive agents. Nordbak’s range of coatings – such as Nordtile®, Nordwear 5 Acid, and Acid Grout – are specifically formulated to resist acids, alkalis, and solvents, making them ideal for high-risk spill containment areas.

Chemical spill zones, whether in manufacturing plants, laboratories, or storage facilities, demand flooring that can resist sudden and frequent exposure to aggressive substances. Unlike general-purpose coatings or untreated concrete, these environments require solutions designed not only for chemical resistance but also for durability and safety.

Why spill zones need specialised coatings

Spill zones are often the first line of defence in preventing accidents from spreading. Unprotected or poorly coated floors allow chemicals to penetrate, resulting in:

- Permanent damage to the substrate.

- Increased risk of slip and trip hazards.

- Contamination issues that impact compliance.

- High repair and maintenance costs.

These risks are amplified in industries handling sulphuric acid, caustic soda, solvents, or other aggressive agents. Only coatings engineered for such exposure provide long-term protection.

Epoxy coatings: a safe and proven choice

Epoxy coatings have become the standard for spill containment areas because they provide a dense, impermeable layer that prevents chemicals from reaching the underlying concrete. Nordbak’s acid-resistant epoxy systems are specifically tested in immersion conditions, ensuring reliability even when spills are prolonged.

- Nordtile® – Offers excellent resistance to sulphuric acid immersion and is suitable for bund walls and spill zones.

- Nordwear 5 Acid – A durable, trowel-applied epoxy system designed for areas where spills combine with mechanical wear.

- Acid Grout – Provides additional strength and acid resistance in containment and spill-prone areas.

These coatings not only resist chemical damage but also provide smooth, easy-to-clean surfaces that reduce safety risks.

Key features of safe spill-zone flooring

The most effective spill-zone coatings share several critical characteristics:

- Seamless application – Prevents acids or solvents from seeping into joints or cracks.

- Chemical resistance – Withstands a wide range of aggressive substances, including sulphuric, hydrochloric, and caustic solutions.

- High compressive strength – Carries the load of equipment, containers, and heavy traffic.

- Abrasion resistance – Stands up to the movement of drums, forklifts, and trolleys.

- Ease of cleaning – Smooth finishes allow rapid spill management.

By meeting all of these requirements, Nordbak’s epoxy coatings turn vulnerable floors into safe, long-lasting assets.

Application best practices

Safe performance in spill zones depends on proper installation. Best practices include:

- Preparing the concrete substrate by removing contaminants and creating a mechanical profile for adhesion.

- Applying the coating at the recommended thickness for the specific chemical risks.

- Allowing full curing before exposing the floor to traffic or spills.

- Conducting regular inspections and timely repairs to maintain the protective barrier.

When these steps are followed, epoxy flooring systems provide reliable long-term performance even in spill-intensive environments.

Example from industry

A chemical storage facility handling sulphuric acid and solvents faced repeated floor damage in its spill containment area. Concrete pitted within months, and clean-up became increasingly difficult. After resurfacing with Nordwear 5 Acid, the spill zone gained a seamless, durable surface resistant to both chemical attack and heavy drum traffic. Years later, the coating remains intact, reducing both maintenance costs and safety risks.

Why Nordbak solutions are trusted

Nordbak has spent more than 40 years developing acid- and chemical-resistant coatings for industries including petrochemicals, mining, and manufacturing. In spill zone applications, their coatings are trusted because they are:

- Proven in aggressive chemical environments.

- Durable under load and abrasion.

- Adaptable for containment, floors, and bund walls.

- Locally manufactured and supported for South African industries.

This combination of chemical resistance and mechanical strength makes Nordbak coatings a safe and dependable choice for spill zones.

Protecting spill zones with confidence

Chemical spill zones demand flooring systems that do more than cover concrete. They must resist aggressive acids and alkalis, stand up to mechanical stress, and provide safe, easy-to-maintain surfaces.

With Nordbak’s acid- and chemical-resistant epoxy systems, facilities can protect their spill zones effectively, ensuring compliance, reducing maintenance, and keeping workers safe.

Can epoxy floors withstand sulfuric acid in industrial plants?

Yes, epoxy floors can withstand sulfuric acid in industrial plants – provided the right acid-resistant system is chosen. Nordbak’s specialised epoxy coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are engineered to resist sulphuric acid immersion of up to 50%, making them ideal for facilities where acid exposure is unavoidable.

Sulphuric acid is one of the most widely used and most corrosive industrial chemicals. Plants involved in mining, metal processing, chemical production, and battery storage all face regular exposure to it. For floors, this means rapid deterioration if they aren’t properly protected. The right epoxy flooring system provides a durable, seamless barrier that resists chemical attack and extends the life of the underlying concrete.

Why sulphuric acid is so aggressive

Sulphuric acid reacts readily with concrete, breaking down the calcium compounds in cement and leaving the surface soft and porous. Even dilute solutions can cause:

- Deep pitting and structural weakening of concrete.

- Surface erosion that creates slip hazards.

- Staining and contamination issues that compromise compliance.

- Rapid loss of load-bearing strength.

In high-concentration areas, unprotected concrete may only survive months before serious damage occurs.

How epoxy flooring resists sulphuric acid

Unlike porous concrete or thin sealants, epoxy coatings form a dense, seamless layer that sulphuric acid cannot penetrate. Nordbak’s acid-resistant epoxy systems are specifically formulated for immersion and spillage conditions common in industrial plants.

- Nordtile® – Proven to resist up to 50% sulphuric acid immersion, suitable for bund walls and floor areas exposed to strong acids.

- Nordwear 5 Acid – A trowelable epoxy system designed for environments where both abrasion and acid attack are present.

- Acid Grout – Used to line and protect areas subject to dilute acid spills, offering compressive strength far greater than concrete.

Together, these systems provide a toolkit for protecting plant floors against even the most aggressive acid conditions.

Factors that determine performance

While epoxy systems can withstand sulphuric acid, performance depends on correct application and site conditions. Key factors include:

- Surface preparation – Concrete must be clean and mechanically profiled for proper adhesion.

- Application thickness – Thicker coatings provide better resistance to immersion and abrasion.

- Curing time – Floors must cure fully before being exposed to chemicals.

- Maintenance – Regular inspections and prompt patch repairs extend service life.

- Traffic load – Facilities with forklifts and heavy equipment require abrasion-resistant systems.

Following these best practices ensures that the epoxy system performs to its full potential.

Example from the field

In a fertiliser production plant, floors around acid mixing tanks were regularly exposed to sulphuric acid splashes. Bare concrete deteriorated quickly, creating pitted surfaces that trapped residues and raised safety concerns. After resurfacing with Nordtile®, the plant achieved a smooth, non-porous surface that resisted ongoing acid exposure. Years later, the coating remains intact, proving the long-term reliability of the system.

Why Nordbak is trusted for acid resistance

For more than 40 years, Nordbak has supplied coatings and linings to industries where sulphuric acid is a daily reality. Their products are:

- Proven in immersion conditions – tested against strong sulphuric acid.

- Durable under load – combining chemical resistance with high compressive strength.

- Versatile – suitable for floors, bund walls, and containment areas.

- Backed by local expertise – designed for South African industrial environments.

This track record means industrial plants can trust Nordbak’s epoxy solutions for safety, compliance, and long-term performance.

Protecting floors from sulphuric acid damage

Epoxy flooring is one of the few reliable ways to safeguard industrial plant floors from sulphuric acid. When the right system is applied correctly, facilities can expect years of protection against one of the most corrosive chemicals in use today.

By choosing Nordbak’s acid-resistant epoxy systems, plants can operate with confidence, knowing their floors will withstand sulphuric acid exposure while maintaining safety, compliance, and durability.

Best practices for applying floor coatings in mining and mineral extraction areas?

The best practices for applying floor coatings in mining and mineral extraction areas include choosing acid- and abrasion-resistant epoxy systems, preparing the concrete substrate correctly, applying the coating at the right thickness, and ensuring regular maintenance. Nordbak’s proven range of protective coatings and wear-resistant compounds are designed specifically for these high-wear, chemically aggressive environments.

Mining and mineral extraction sites are among the harshest industrial environments for floors. Heavy equipment, abrasive dust, chemical processing, and continuous traffic all take their toll. Without the right coating, concrete floors quickly break down – leading to costly repairs, unsafe conditions, and production downtime. Getting the application right from the start is what ensures long-term performance.

Why mining environments demand specialised flooring

Unlike typical industrial plants, mining and mineral extraction facilities are exposed to unique challenges:

- Abrasive dust and slurry that grind away at surfaces.

- Acidic and alkaline solutions from processing operations.

- Heavy machinery and traffic that stress the flooring constantly.

- Moisture and temperature fluctuations that weaken unprotected concrete.

Standard paints or sealants don’t last long under these conditions. A specialised epoxy or co-polymer coating is the only way to provide reliable protection.

Step 1: Selecting the right coating system

The first step in best practice is product selection. Mining floors require coatings that deliver both abrasion resistance and chemical resistance. Nordbak offers several solutions tailored to these needs:

- Nordwear 5 Acid – Designed for environments with acidic slurries and salts.

- Nordwear 8 – High-impact, abrasion-resistant system ideal for chutes and heavy-wear floors.

- Nordtile® – Proven to withstand up to 50% sulphuric acid in immersion, while maintaining excellent wear properties.

- Fixwear – A versatile wear compound used to patch or reline high-traffic surfaces.

By matching the coating to the specific risks of the site, mine operators ensure maximum service life.

Step 2: Proper surface preparation

Even the best coating will fail if the substrate isn’t prepared correctly. In mining facilities, where dust and residues are common, preparation is critical. Best practice includes:

- Cleaning the floor thoroughly to remove oils, dust, and contaminants.

- Mechanically profiling the surface (e.g., shot blasting) to improve adhesion.

- Repairing cracks or voids with suitable epoxy grouts before coating.

A properly prepared floor provides a strong bond for the epoxy system, ensuring it performs as designed.

Step 3: Applying at the right thickness

Floor coatings in mining environments need to be applied at adequate thickness to withstand heavy wear. Thin coatings may look fine initially but will wear through quickly. Nordbak’s epoxy compounds are designed to be applied at robust thicknesses, often several millimetres, depending on the level of exposure. The thicker the coating, the greater the protection against abrasion and chemical attack.

Step 4: Curing and protection during installation

One of the biggest mistakes in coating application is rushing the curing process. Mining operations are under pressure to minimise downtime, but applying loads or traffic too soon compromises the integrity of the floor. Best practice means allowing the full curing time specified for the product, ensuring maximum hardness and resistance before the floor is returned to service.

Step 5: Ongoing maintenance and inspection

Even the most durable floor coatings benefit from regular maintenance. Best practice includes:

- Inspecting coated areas for early signs of wear.

- Promptly repairing damaged patches to prevent further degradation.

- Cleaning floors regularly to remove abrasive dust and chemical residues.

Nordbak’s trowelable systems, such as Fixwear and Nordwear compounds, make patch repairs straightforward, extending the lifespan of the floor.

Example from the field

Consider a mineral extraction plant where slurry spillage and acidic solutions frequently reached the floor near processing tanks. The bare concrete began to pit and break apart within a year, creating a serious safety concern. After resurfacing with Nordwear 5 Acid at the recommended thickness, the plant achieved a durable, seamless floor that resisted both abrasion and chemical attack. Regular inspections and timely patching have kept the surface intact for years, avoiding costly shutdowns.

Why Nordbak is trusted in mining

With over 40 years of experience, Nordbak has developed coatings specifically for mining and mineral extraction environments. Their products are:

- Proven under high abrasion and chemical stress.

- Locally manufactured and supported for South African mining conditions.

- Adaptable for both new applications and repair work.

- Backed by decades of field performance in some of the harshest industrial sites.

Building resilience into mining floors

Mining operations rely on infrastructure that can withstand relentless wear and harsh chemicals. By following best practices – choosing the right coating, preparing the substrate properly, applying at sufficient thickness, curing fully, and maintaining regularly – operators can ensure floors last for many years without failure.

With Nordbak’s specialised epoxy systems, mines and mineral extraction facilities can protect their concrete floors against abrasion and corrosion, keeping operations safe, efficient, and compliant.

How long does epoxy flooring last in petrochemical facilities?

High-quality epoxy flooring in petrochemical facilities can last 10–20 years, provided the correct acid- and chemical-resistant system is installed and properly maintained. Nordbak’s epoxy coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are designed to withstand the harsh chemicals, abrasion, and heavy loads typical of petrochemical plants—delivering long-term performance well beyond standard flooring options.

Petrochemical environments are some of the toughest in industry. Floors are exposed to acids, alkalis, solvents, fuels, and constant mechanical wear. In this setting, the question isn’t just how long does epoxy flooring last? It’s how well is it suited to survive in an environment where failure is costly?

What shortens flooring lifespan in petrochemical plants

Concrete floors in petrochemical facilities face a unique set of challenges. Even coated surfaces can degrade prematurely if the wrong product is applied. Common threats include:

- Chemical attack from hydrocarbons, acids, and alkalis.

- Abrasion from equipment, pallets, and heavy foot traffic.

- Thermal stress from fluctuating temperatures and heat exposure.

- Spill frequency that requires aggressive cleaning regimes.

Without the right protective system, floors can show damage within just a few years—leading to costly resurfacing and downtime.

Why epoxy systems last longer

Epoxy flooring creates a seamless, non-porous barrier that resists chemical penetration. Nordbak’s acid- and abrasion-resistant epoxies are engineered to handle the chemical complexity of petrochemical facilities, giving them a much longer service life compared to conventional coatings.

Products like Nordwear 5 Acid and Nordtile® have been proven to resist sulphuric acid immersion up to 50%, while also offering high impact and abrasion resistance. This combination ensures floors don’t just survive chemical exposure—they stay operational under the weight and wear of petrochemical operations.

Factors influencing lifespan

While epoxy flooring can last up to two decades, the actual lifespan depends on several factors:

- Correct product selection – Using acid- and chemical-resistant coatings designed for petrochemical environments.

- Surface preparation – Properly prepared concrete ensures maximum bond strength.

- Thickness of application – Adequate build-up provides better resistance to chemicals and abrasion.

- Maintenance – Regular cleaning and prompt spill management extend coating performance.

- Traffic load – Facilities with high forklift or machinery traffic may need thicker or reinforced systems.

With Nordbak’s experience, flooring systems can be tailored to meet the specific demands of each petrochemical plant, ensuring maximum longevity.

Cost vs. value over time

At first glance, specialised epoxy coatings can seem like a higher upfront investment. But in a petrochemical facility, lifespan is where value is truly measured. A properly applied Nordbak epoxy system that lasts 15 years or more outperforms cheaper coatings that fail in five, delivering far lower lifecycle costs. Reduced downtime, lower maintenance, and fewer resurfacing projects all contribute to the return on investment.

Practical example

Imagine a petrochemical storage facility where hydrochloric acid and caustic soda are regularly handled. Standard epoxy paint was applied years ago, but within five years the floor began blistering and peeling under chemical attack. After resurfacing with Nordbak Acid Grout and Nordwear 5 Acid, the floor not only resists chemical degradation but also withstands the heavy loads of chemical drums and forklifts. The result is a floor expected to last more than a decade without major repairs.

Why Nordbak is trusted in petrochemicals

For over 40 years, Nordbak has supplied protective coatings to industries where chemical resistance is non-negotiable. In petrochemicals, Nordbak coatings are trusted because they combine:

- Proven acid and chemical resistance – against sulphuric, hydrochloric, alkalis, and salts.

- High compressive and abrasion strength – essential for heavy-duty floors.

- Durability under thermal and mechanical stress – tested in demanding plants across industries.

- Local expertise – tailor-made solutions and on-site application support in South Africa.

Building floors that last decades, not years

In petrochemical facilities, epoxy flooring is not just a protective layer—it’s a safeguard against costly downtime, safety risks, and structural damage. With the right system, floors can last 10–20 years, saving money and ensuring compliance with environmental and safety standards.

By choosing Nordbak’s acid- and chemical-resistant epoxy coatings, petrochemical plants gain the confidence that their floors will stand up to decades of demanding service.

What type of floor coating resists corrosion in acid production environments?

The most effective floor coating for acid production environments is a high-performance acid-resistant epoxy system. Nordbak’s acid-resistant coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are specifically formulated to resist sulphuric acid, alkalis, and other aggressive chemicals commonly found in acid manufacturing.

Acid production plants present one of the harshest environments for flooring. From sulphuric acid processing to handling ammonium and sodium sulphates, floors are constantly exposed to corrosive substances that can destroy unprotected concrete. To maintain safety, compliance, and operational efficiency, facilities need floor coatings designed to withstand this chemical onslaught.

Why acid production floors are so vulnerable

Concrete on its own cannot survive in acid-heavy environments. It is porous, meaning that even small acid spills seep into the material, reacting with the lime in cement and breaking down its structure. Over time, this leads to:

- Deep pitting and crumbling of the floor.

- Weakening of structural integrity.

- Hazardous surfaces that put workers at risk.

- Escalating repair costs and downtime.

For acid production environments, unprotected concrete is simply not an option.

Acid-resistant epoxy coatings: the proven solution

Epoxy coatings provide a seamless, impermeable barrier that shields concrete from acids, alkalis, and salts. Unlike surface paints or tile systems, epoxy linings don’t leave weak points for acids to penetrate. Nordbak’s acid-resistant epoxy formulations are designed for precisely this purpose – offering long-term durability even under constant chemical exposure.

For example, Nordtile® and Nordwear 5 Acid are trowelable epoxy systems with exceptional acid resistance, proven to withstand up to 50% sulphuric acid in immersion. These products are not just resistant on the surface – they are built to hold up under prolonged and aggressive contact with acids.

Meeting both chemical and mechanical demands

In acid production, it’s not only about resisting chemicals. Floors also face heavy machinery, constant foot traffic, and regular cleaning. That’s why Nordbak’s epoxy systems combine chemical resilience with high compressive strength and abrasion resistance. Products like Fixwear and Nordwear 8 are designed to cope with both wear and corrosive attack, making them ideal for plant floors that must endure years of daily stress.

Compliance and safety considerations

Acid production facilities are subject to strict occupational health and environmental regulations. Damaged flooring poses risks of chemical seepage, environmental contamination, and workplace hazards. By installing acid-resistant epoxy flooring, plant managers can address compliance requirements proactively while improving workplace safety. Smooth, intact surfaces are easier to clean, reducing both risk and maintenance costs.

Real-world application example

Consider a sulphuric acid production plant where bund walls and surrounding floors face constant splashes and mist exposure. Within months, bare concrete begins to pit, turning the floor into a maintenance nightmare and a safety concern. After resurfacing with a Nordbak acid-resistant epoxy coating, the plant achieves a seamless, non-porous surface that resists corrosion, remains easy to clean, and meets audit requirements with confidence.

Why Nordbak is the trusted choice

Nordbak has been protecting industrial surfaces for more than 40 years, supplying acid-resistant linings and coatings to industries including mining, petrochemicals, and cement manufacturing. For acid production environments, Nordbak’s solutions stand out because they are:

- Proven in immersion conditions – withstanding direct and prolonged acid contact.

- Durable under heavy loads – combining compressive strength with abrasion resistance.

- Adaptable to different applications – suitable for floors, bund walls, tanks, and spill areas.

- Backed by local expertise – developed and manufactured in South Africa for demanding industrial use.

These coatings aren’t generic products – they are specialised systems designed and tested for the most corrosive environments.

Building long-term protection into your plant

In acid production, the choice of floor coating is not just about surface protection – it’s about long-term reliability, reduced maintenance, and workplace safety. High-performance acid-resistant epoxy systems, like those offered by Nordbak, transform vulnerable concrete floors into durable assets capable of withstanding years of exposure to the harshest chemicals.

By investing in the right flooring system, acid production plants safeguard both their infrastructure and their people. With Nordbak, you gain coatings engineered for corrosion resistance, mechanical strength, and compliance peace of mind.

Corporate & Internal Events

Inside Nordbak – News, Milestones & Team Highlights

Team Nordbak Goes Fishing

The Nordbak Sales team were lucky fishes when they got to go participate in the National Myn Manne Competition in March this year.

A Colourful Year-End Function

The combined function between the admin and the factory personnel was a fun event, which promoted team spirit, a key to a successful business.

Phalaborwa Soccer Team Gets a Kick

The Bollanoto Bluebirds soccer club got a pleasant surprise when they were handed a soccer kit donation from Nordbak (Pty) Ltd.’s branch manager, Antoon Korff – at the Nordbak Phalaborwa Branch on Saturday, 26 November.

Contact Details

Address: 193 Immelman Road, Wadeville, Germiston, 1428

Phone: +27-11-824-1640/7

Email: support@nordbak.co.za

Get in Touch with Nordbak

At Nordbak we’re committed to providing innovative solutions and excellent customer support. Let’s work together to find the right solution for your needs.

Fill out the contact form below, and our team will get back to you.

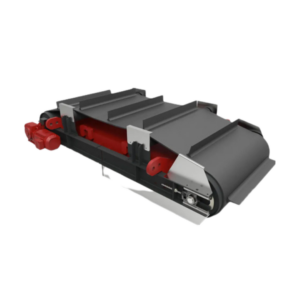

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

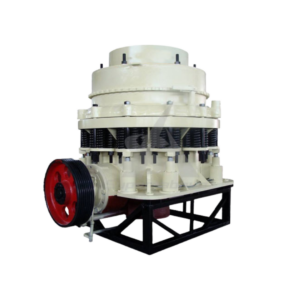

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.