Case Studies

& Reviews

PRODUCT OVERVIEW

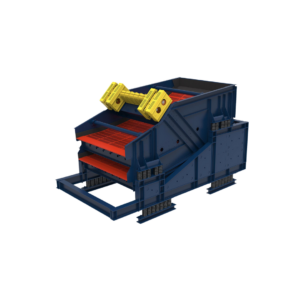

INNOVATIVE SOLUTIONS FOR INDUSTRIAL CHALLENGES

Tackling Wear and Abrasion

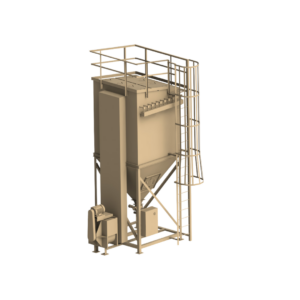

Industries such as mining, cement, and power generation experience severe equipment wear due to continuous exposure to harsh materials. Nordbak’s epoxy-based wear-resistant coatings provide a protective barrier against abrasive forces, extending the lifespan of critical components like chutes, hoppers, and mill liners. These coatings reduce maintenance costs and minimize unexpected failures, ensuring seamless operations.

Combating Corrosion and Chemical Attack

Industrial equipment often operates in environments where exposure to chemicals and moisture leads to corrosion. Nordbak’s chemical-resistant linings and coatings form an impermeable shield against corrosive substances, preserving the integrity of machinery and infrastructure. This is particularly beneficial in industries such as petrochemical processing and wastewater treatment, where chemical exposure is unavoidable.

Nordbak Solutions at Work

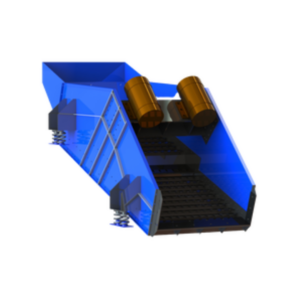

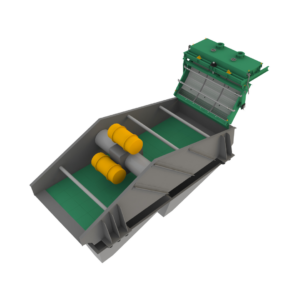

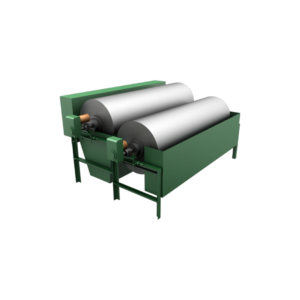

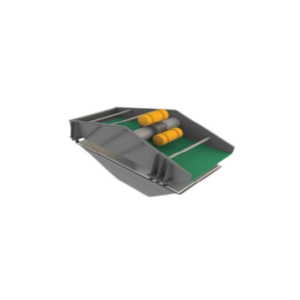

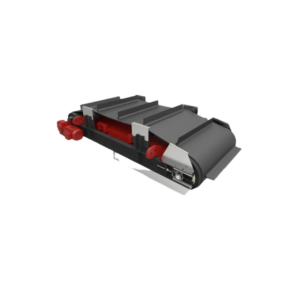

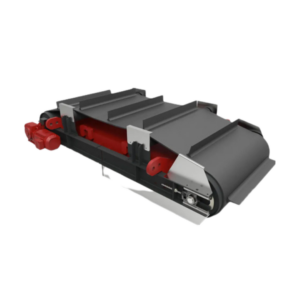

Ceramic Diamond High-Impact

Pulley Lagging Application

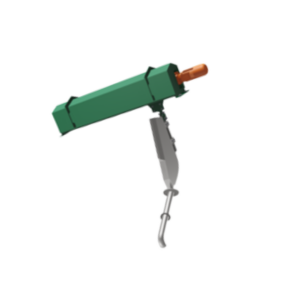

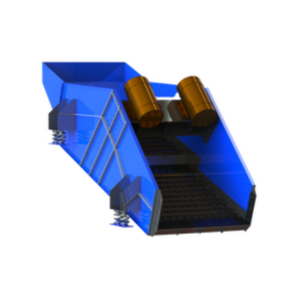

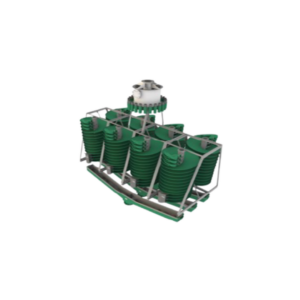

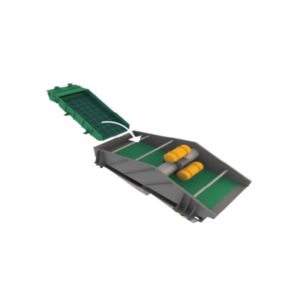

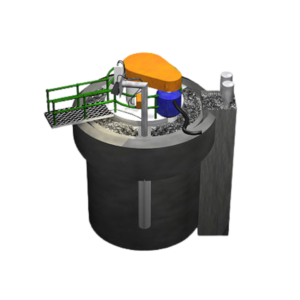

Agitator Blades

Nordwear 5 Application

Customer Challenges

A Beverage manufacturing customer required a solution to protect a newly built Caustic Bund Wall Area.

A mining customer required a solution as they faced challenges with corrosion and metal degradation within CIL Tanks.

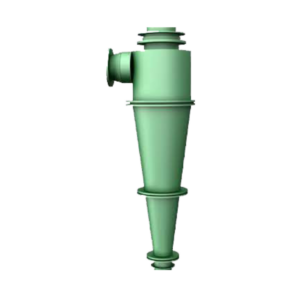

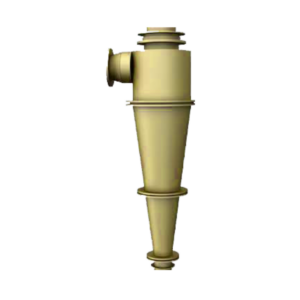

A large industrial customer experienced a crack on the cone of a manifold.

A mining customer required a solution as they faced challenges with corrosion and metal degradation within CIL Tanks.

Proven Performance, Trusted Results!

“The life of the blades and side plates is prolonged by 3 times the normal lifespan. Financially worth the coating, we are saving a lot on downtime expenses too.”

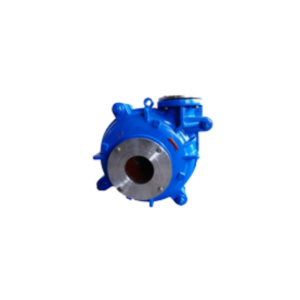

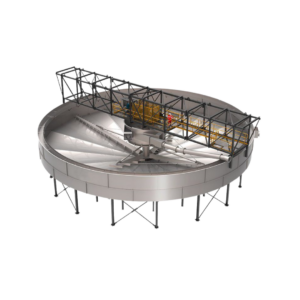

Universal Fans

Nordcoat 2 Black – Impellers for Sugar Mills (13/10/2022)

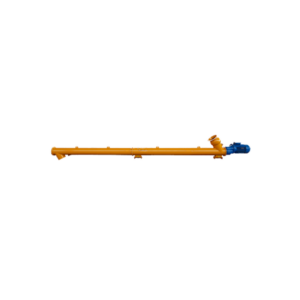

“Augers and casings did not last for the harvesting season, they had to be replaced and we suffered huge financial and downtime implications. Once we started using Nordwear 5 Acid the lifespan of our equipment and often will only need to be replaced the next harvesting season.”

Kempston Agri

Nordwear 5 Acid – Farming Industry Implements (13/10/2022)

“Nordbak’s products have been proven to last up to 7 years and longer.”

Sasol Bosjespruit

Hi-Impact Pulley – Conveyor Pulleys

Ready to Transform Your Project?

Don’t let project challenges hold you back. Reach out to Nordbak’s expert team for tailored solutions that ensure success.

Contact us now to discuss your needs and request a consultation.

Contact Details

Address: 193 Immelman Road, Wadeville, Germiston, 1428

Phone: +27-11-824-1640/7

Email: support@nordbak.co.za

Get in Touch with Nordbak

At Nordbak we’re committed to providing innovative solutions and excellent customer support. Let’s work together to find the right solution for your needs.

Fill out the contact form below, and our team will get back to you.

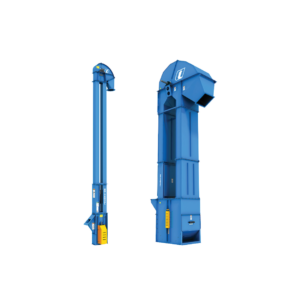

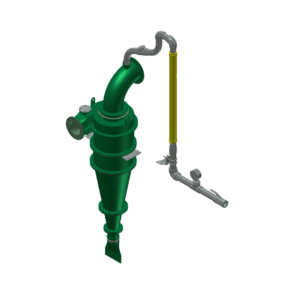

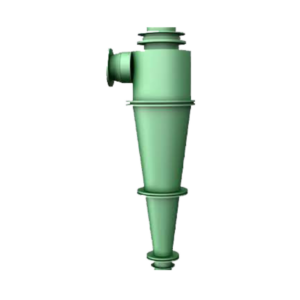

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

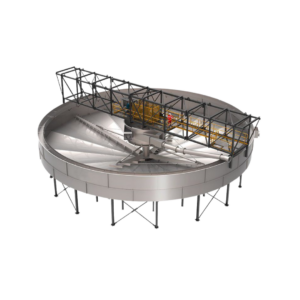

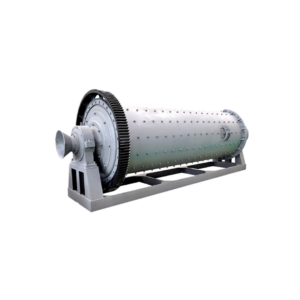

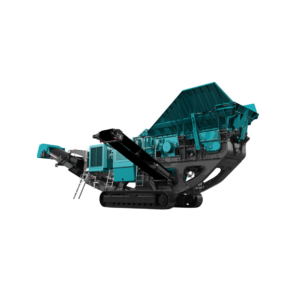

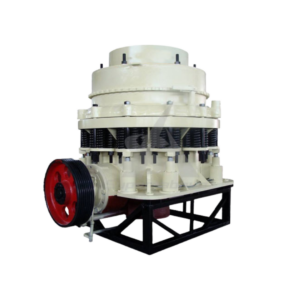

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.