Crusher Backing

and Mill Repairs

Industrial-Grade Crusher Backing Solutions for Maximum Equipment Protection

When every millisecond of uptime matters, Nordbak backing compounds deliver peace of mind. From primary crushers to high-impact mills, our co-polymer systems lock in liners, seal gaps, and absorb shock – without melting, special gear, or guesswork.

Whether you’re patching narrow voids or securing seven-foot gyratory crushers, we’ve got a solution built for the wear and tear of heavy industry.

Need help choosing the right product? Speak to our team – we’re here to help.

20kg Part number 9505-9908

- Suitable for Primary Crushers

- Operational time: 8 hours @ 25°C

- Tough and resilient

NORDBAK® PRIMARY BACKING is a blended co-polymer product with high compressive and high-impact strengths and improved tensile strength. It is non-flammable, needs no melting or special equipment and has a high volumetric stability that eliminates the formation of gaps between backing and liners or support structures.

PRIMARY BACKING is ideally suited to be used in the following Mining Sectors:

- Chrome

- Platinum

- Manganese

- Iron ores

Trusted to improve and increase the life span of Crusher liner plates in Mining Equipment.

20kg Part number 9505-9987

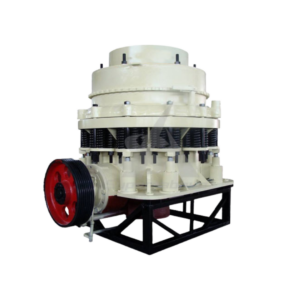

- Suitable for large Gyratory and Cone Crushers

- Operational time: 6 hours @ 25°C

- Saves on downtime and maintenance costs

NORDBAK® HI-PERFORMANCE BACKING is a 100% solids co-polymer system for backing metal wear plates in large gyratory and seven-foot cone crushers. This product offers excellent impact strength, resilience, and high compression and tensile strength. It is non-flammable, needs no melting or special equipment and has a high volumetric stability that eliminates the formation of gaps between backing and liners or support structures.

HI-PERFORMANCE BACKING is ideally suited to be used in the following Mining Sectors:

- Chrome

- Platinum

- Manganese

- Iron ores

Ideally suited for high crushing and extreme impact conditions.

10kg Part number 9505-9901

20kg Part number 9505-9905

- Operational time: 6 hours @ 25°C

- Compressive strength in excess of 135MPa

- 100% solids co-polymer system

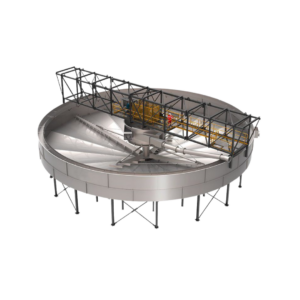

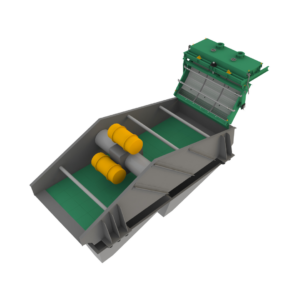

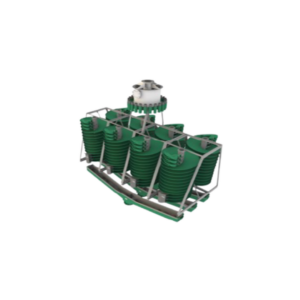

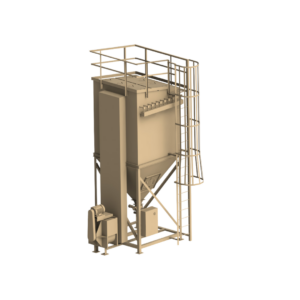

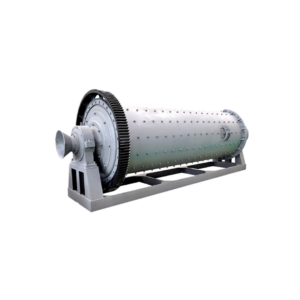

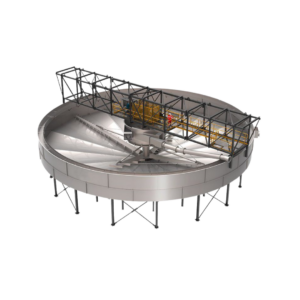

NORDBAK® Standard Backing materials are tough and resilient and are ideal for Cone Crushers, Primary Gyratory Crushers and Rotating Mills.

STANDARD BACKING is ideally suited to be used in the following area:

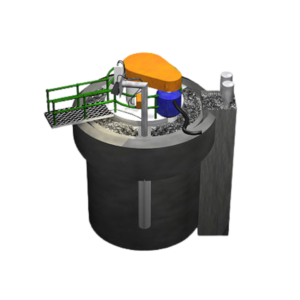

- Cone Crushers

- Primary Gyratory Crushers

- Rotating Mills

- Pulverizes

- Other reduction machinery

- 5-foot Crushers

- Gold, Copper and low-strength ores

10kg Part number 7459-9998

20kg Part number 9505-9915

- Operational time: 6 hours @ 25°C

- Compressive strength in excess of 135MPa

- Non-hazardous

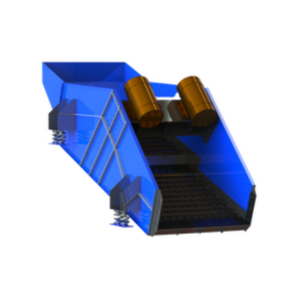

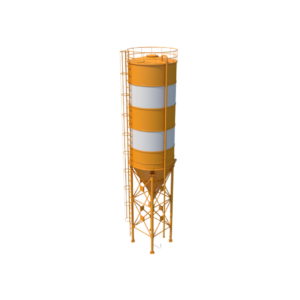

NORDBAK® SUPERBAK BACKING materials are tough, resilient and ideal for Heavy Reduction Machinery and Crushing Operations.

Nordbak SUPERBAK BACKING is ideally suited to be used in the following

- Cone Crushers

- Primary Gyratory Crushers

- Rotating Mills

- Pulverizes

- Other reduction machinery

- 5-foot crushers

- Gold, Copper and low-strength ores

10kg Part number 7459-9999

- Operational time: 6 hours @ 25°C

- Compressive strength 140 MPa

- Easy and safe to use

NORDBAK® backing materials are tough, resilient and ideal for applications where narrow orifices prevent the use of a regular backing.

Nordbak LOW-VISCOSITY BACKING is ideally suited to be used where narrow openings prevent the use of our other Backings.

2.8kg Part number 9505-9960

- Maximum operation temperature 140°C

- Compressive strength in excess of 83MPa

- Saves on downtime and maintenance costs

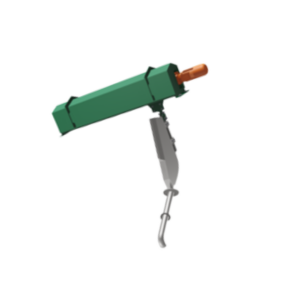

NORDBAK® LOCKING COMPOUND is a high-temperature and high-impact material for locking inner and outer eccentric bushes in Symons Cone Crushers. No special training or experience is required as the LOCKING COMPOUND is mixed and poured at room temperature. The LOCKING COMPOUND has a high coefficient of thermal conductivity, which reduces overheating and can be drilled to facilitate the removal of worn bushes.

Nordbak LOCKING COMPOUND is specifically designed to lock the inner and outer eccentric bushes in Symons Cone Crushers.

12kg product number 9505-9935

- Just like steel that can resist corrosion and chemical abrasion

- Excellent material for fast, low-cost repairs to steel, iron, or other ferrous castings

NORDBAK® STEEL TROWEL MIX is a 100% solids epoxy resin system filled with steel powder. Once hardened it can be machined, drilled, tapped, or filed just like steel. Worn or corroded surfaces can be built up with STEEL TROWEL MIX and easily machined back to the original shape.

Cures without heat or special devices, and is non-shrinking.

Nordbak STEEL TROWEL MIX can be used for these other applications:

- Surface coating to protect against abrasion

- Repair of broken metal parts

- A tooling jig fixture or modeling material

STEEL TROWEL MIX also bonds securely to:

- Iron

- Steel

- Ceramic

- Carbide

- Concrete

- Wood and chemical corrosion

Technical Infomation:

- Compressive strength 100MPa

- Hardening time @ 21°C is 3 hours

4 x 1kg kit size product number 9505-9919

12kg kit size product number 9505-9918

- Trowels easily in place

- Compressive strength 110 MPa

- Serves to secure liner bolts in their holes

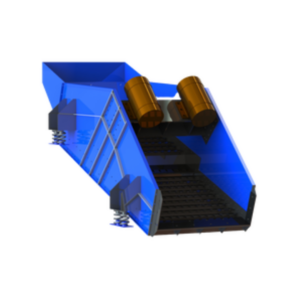

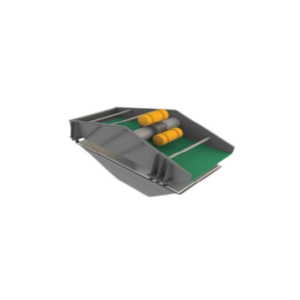

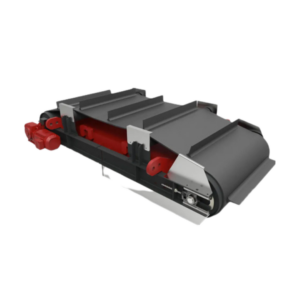

NORDBAK® TROWEL MIX is ideal for backing liners in all types of mills. Its paste-like consistency eliminates the need for dismantling the mill or removing the grinding charge. Product trowels are easily in place in any mill area where backing material is required.

TROWEL MIX is useful in the following:

- Backing headliners

- Division heads

- Diaphragms

Box of 24 product number 7459-9885B

- Works like putty, sticks like glue

- Mold to any shape

- Fast – workable for 5 minutes and sets in 15 minutes

- Drill, saw, tap, file or paint after material is cured

NORDBAK® STEEL STICKS are an epoxy compound filled with steel with unlimited uses for general repairs. Adheres to damp surfaces and cures under water. Use as putty or an adhesive. No measuring or mess, simply cut off what you need. Chemical and corrosion resistant. Can be used on a number of different types of materials.

STEEL STICK can be used to repair the following:

- Plumbing

- Ductwork

- Fillets

- Impellers

- Anchor Bolts

- Tooling Jigs

- Chutes

- Joints

- Pump Casings

- Molds

- Gear Casing

- Tanks

- Pipe Fittings and many more…

Contact Details

Address: 193 Immelman Road, Wadeville, Germiston, 1428

Phone: +27-11-824-1640/7

Email: support@nordbak.co.za

Get in Touch with Nordbak

At Nordbak we’re committed to providing innovative solutions and excellent customer support. Let’s work together to find the right solution for your needs.

Fill out the contact form below, and our team will get back to you.

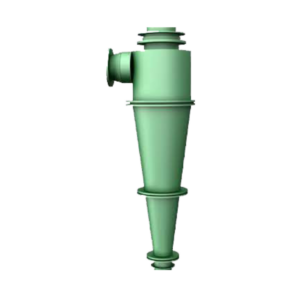

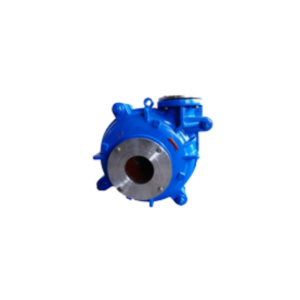

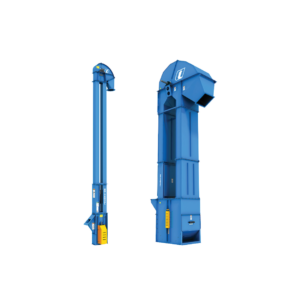

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.