Blog

TEAM NORDBAK GOES FISHING

The Nordbak Sales team were lucky fishes when they got to go participate in the National Myn Manne Competition in March this year.

A COLOURFUL YEAR END FUNCTION

The combined function between the admin and the factory personnel was a fun event, which promoted team spirit, a key to a successful business

PHALABORWA SOCCER TEAM GETS A KICK START

The Bollanoto Bluebirds soccer club got a pleasant surprise when they were handed a soccer kit donation

from Nordbak (Pty) Ltd.’s branch manager, Antoon Korff – at the Nordbak Phalaborwa Branch on Saturday, 26 November 2022.

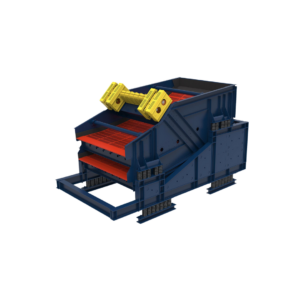

1. Prevent rust and corrosion: Heavy–duty machinery is often exposed to a variety of environmental factors that can cause rust and corrosion, so it is important to use a coating or lining to protect the metal from these elements.

2. Reduce wear and tear: Heavy–duty machinery is subject to a lot of wear and tear, so it is important to use a protective coating to reduce the amount of damage and prolong the life of the machinery.

3. Protect from chemicals: Some heavy–duty machinery is exposed to chemicals, so it is important to protect it from chemical damage with the use of a protective coating.

4. Enhance aesthetics: A protective coating can enhance the aesthetic appeal of the machinery and make it look more attractive.

5. Increase safety: Protective coatings can also help to increase safety by reducing the risk of slips and falls on the machinery.

Contact Us

Phone

Nordbak® polymer-based products are used successfully in general engineering, petrochemicals, building and civil construction, sugar mills, cement manufacture and water reticulation.

Certificate Number: 8332

ISO 9001:2015

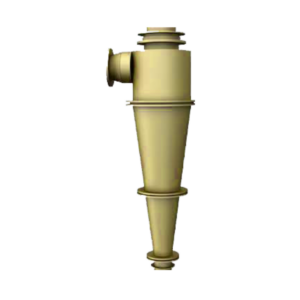

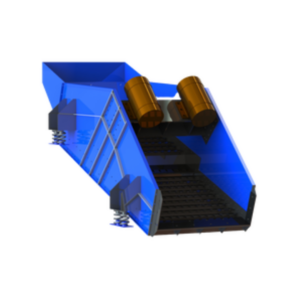

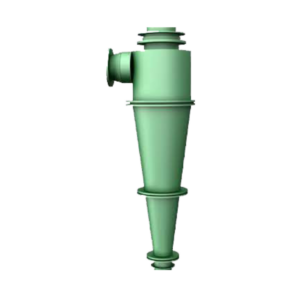

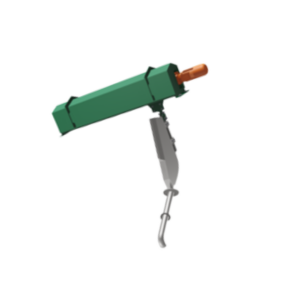

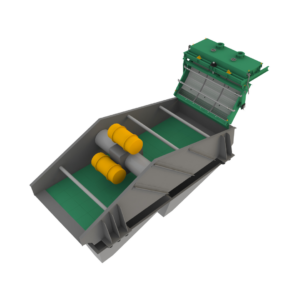

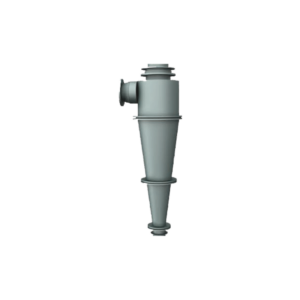

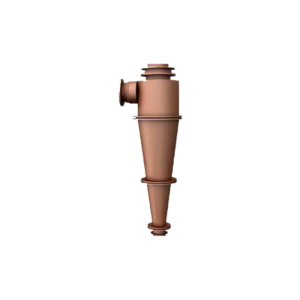

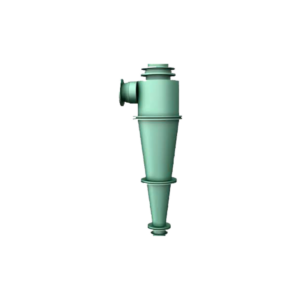

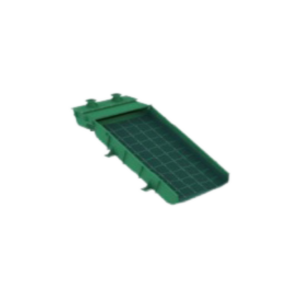

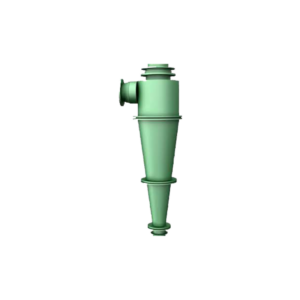

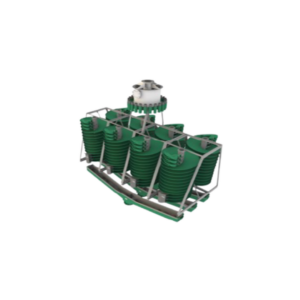

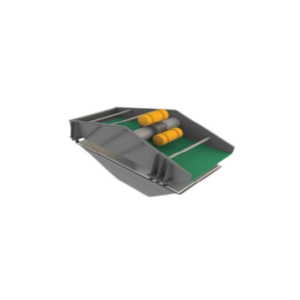

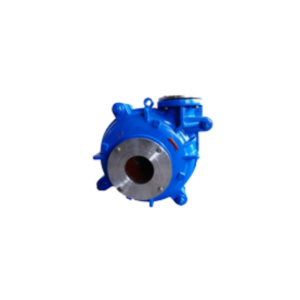

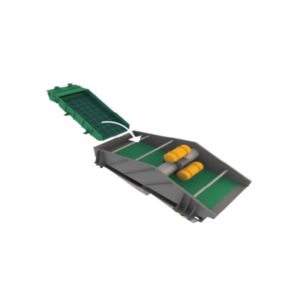

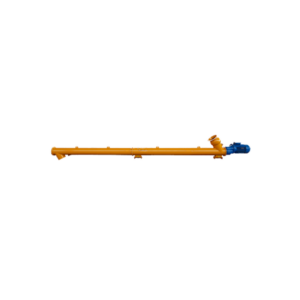

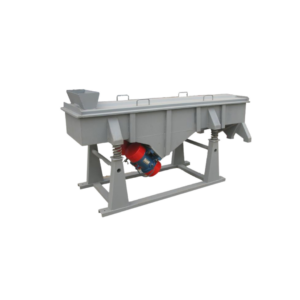

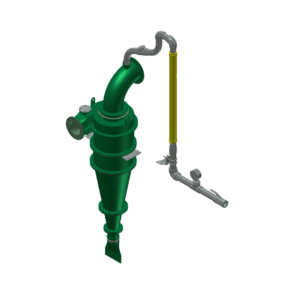

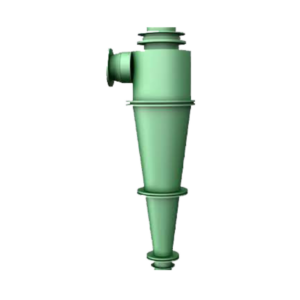

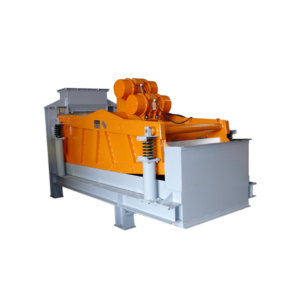

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

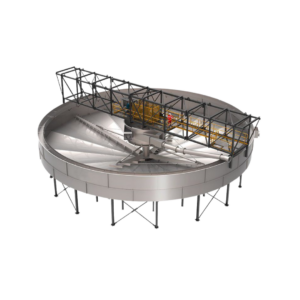

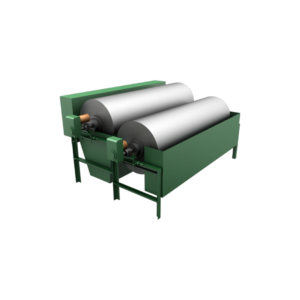

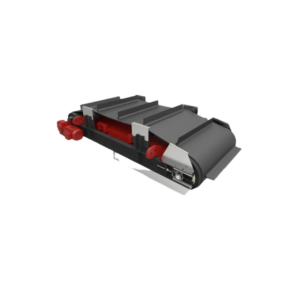

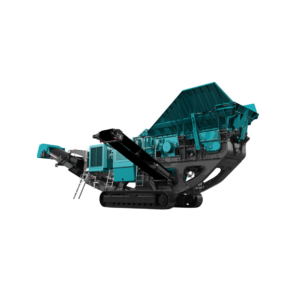

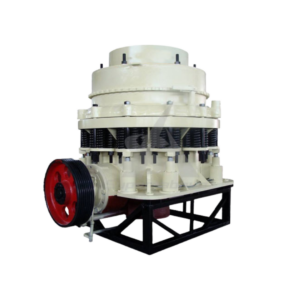

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.