The best practices for applying floor coatings in mining and mineral extraction areas include choosing acid- and abrasion-resistant epoxy systems, preparing the concrete substrate correctly, applying the coating at the right thickness, and ensuring regular maintenance. Nordbak’s proven range of protective coatings and wear-resistant compounds are designed specifically for these high-wear, chemically aggressive environments.

Mining and mineral extraction sites are among the harshest industrial environments for floors. Heavy equipment, abrasive dust, chemical processing, and continuous traffic all take their toll. Without the right coating, concrete floors quickly break down – leading to costly repairs, unsafe conditions, and production downtime. Getting the application right from the start is what ensures long-term performance.

Why mining environments demand specialised flooring

Unlike typical industrial plants, mining and mineral extraction facilities are exposed to unique challenges:

- Abrasive dust and slurry that grind away at surfaces.

- Acidic and alkaline solutions from processing operations.

- Heavy machinery and traffic that stress the flooring constantly.

- Moisture and temperature fluctuations that weaken unprotected concrete.

Standard paints or sealants don’t last long under these conditions. A specialised epoxy or co-polymer coating is the only way to provide reliable protection.

Step 1: Selecting the right coating system

The first step in best practice is product selection. Mining floors require coatings that deliver both abrasion resistance and chemical resistance. Nordbak offers several solutions tailored to these needs:

- Nordwear 5 Acid – Designed for environments with acidic slurries and salts.

- Nordwear 8 – High-impact, abrasion-resistant system ideal for chutes and heavy-wear floors.

- Nordtile® – Proven to withstand up to 50% sulphuric acid in immersion, while maintaining excellent wear properties.

- Fixwear – A versatile wear compound used to patch or reline high-traffic surfaces.

By matching the coating to the specific risks of the site, mine operators ensure maximum service life.

Step 2: Proper surface preparation

Even the best coating will fail if the substrate isn’t prepared correctly. In mining facilities, where dust and residues are common, preparation is critical. Best practice includes:

- Cleaning the floor thoroughly to remove oils, dust, and contaminants.

- Mechanically profiling the surface (e.g., shot blasting) to improve adhesion.

- Repairing cracks or voids with suitable epoxy grouts before coating.

A properly prepared floor provides a strong bond for the epoxy system, ensuring it performs as designed.

Step 3: Applying at the right thickness

Floor coatings in mining environments need to be applied at adequate thickness to withstand heavy wear. Thin coatings may look fine initially but will wear through quickly. Nordbak’s epoxy compounds are designed to be applied at robust thicknesses, often several millimetres, depending on the level of exposure. The thicker the coating, the greater the protection against abrasion and chemical attack.

Step 4: Curing and protection during installation

One of the biggest mistakes in coating application is rushing the curing process. Mining operations are under pressure to minimise downtime, but applying loads or traffic too soon compromises the integrity of the floor. Best practice means allowing the full curing time specified for the product, ensuring maximum hardness and resistance before the floor is returned to service.

Step 5: Ongoing maintenance and inspection

Even the most durable floor coatings benefit from regular maintenance. Best practice includes:

- Inspecting coated areas for early signs of wear.

- Promptly repairing damaged patches to prevent further degradation.

- Cleaning floors regularly to remove abrasive dust and chemical residues.

Nordbak’s trowelable systems, such as Fixwear and Nordwear compounds, make patch repairs straightforward, extending the lifespan of the floor.

Example from the field

Consider a mineral extraction plant where slurry spillage and acidic solutions frequently reached the floor near processing tanks. The bare concrete began to pit and break apart within a year, creating a serious safety concern. After resurfacing with Nordwear 5 Acid at the recommended thickness, the plant achieved a durable, seamless floor that resisted both abrasion and chemical attack. Regular inspections and timely patching have kept the surface intact for years, avoiding costly shutdowns.

Why Nordbak is trusted in mining

With over 40 years of experience, Nordbak has developed coatings specifically for mining and mineral extraction environments. Their products are:

- Proven under high abrasion and chemical stress.

- Locally manufactured and supported for South African mining conditions.

- Adaptable for both new applications and repair work.

- Backed by decades of field performance in some of the harshest industrial sites.

Building resilience into mining floors

Mining operations rely on infrastructure that can withstand relentless wear and harsh chemicals. By following best practices – choosing the right coating, preparing the substrate properly, applying at sufficient thickness, curing fully, and maintaining regularly – operators can ensure floors last for many years without failure.

With Nordbak’s specialised epoxy systems, mines and mineral extraction facilities can protect their concrete floors against abrasion and corrosion, keeping operations safe, efficient, and compliant.

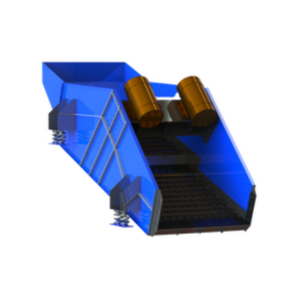

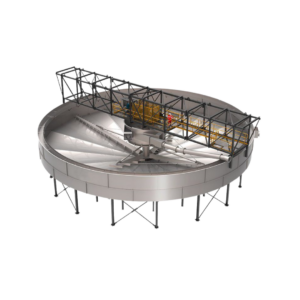

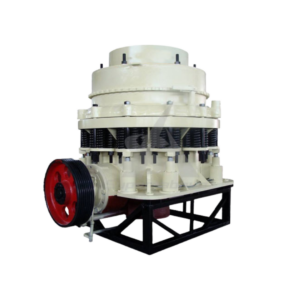

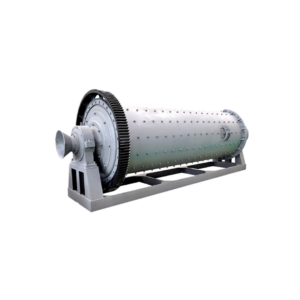

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

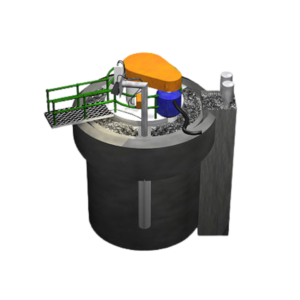

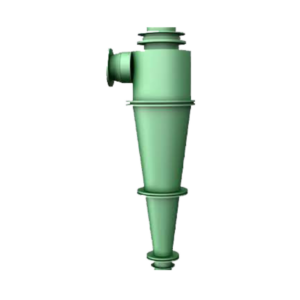

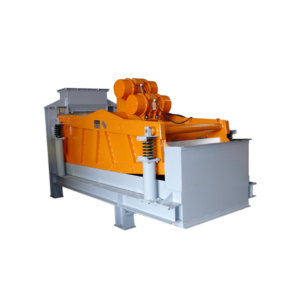

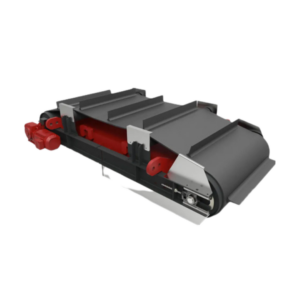

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.