High-quality epoxy flooring in petrochemical facilities can last 10–20 years, provided the correct acid- and chemical-resistant system is installed and properly maintained. Nordbak’s epoxy coatings, such as Nordtile®, Nordwear 5 Acid, and Acid Grout, are designed to withstand the harsh chemicals, abrasion, and heavy loads typical of petrochemical plants—delivering long-term performance well beyond standard flooring options.

Petrochemical environments are some of the toughest in industry. Floors are exposed to acids, alkalis, solvents, fuels, and constant mechanical wear. In this setting, the question isn’t just how long does epoxy flooring last? It’s how well is it suited to survive in an environment where failure is costly?

What shortens flooring lifespan in petrochemical plants

Concrete floors in petrochemical facilities face a unique set of challenges. Even coated surfaces can degrade prematurely if the wrong product is applied. Common threats include:

- Chemical attack from hydrocarbons, acids, and alkalis.

- Abrasion from equipment, pallets, and heavy foot traffic.

- Thermal stress from fluctuating temperatures and heat exposure.

- Spill frequency that requires aggressive cleaning regimes.

Without the right protective system, floors can show damage within just a few years—leading to costly resurfacing and downtime.

Why epoxy systems last longer

Epoxy flooring creates a seamless, non-porous barrier that resists chemical penetration. Nordbak’s acid- and abrasion-resistant epoxies are engineered to handle the chemical complexity of petrochemical facilities, giving them a much longer service life compared to conventional coatings.

Products like Nordwear 5 Acid and Nordtile® have been proven to resist sulphuric acid immersion up to 50%, while also offering high impact and abrasion resistance. This combination ensures floors don’t just survive chemical exposure—they stay operational under the weight and wear of petrochemical operations.

Factors influencing lifespan

While epoxy flooring can last up to two decades, the actual lifespan depends on several factors:

- Correct product selection – Using acid- and chemical-resistant coatings designed for petrochemical environments.

- Surface preparation – Properly prepared concrete ensures maximum bond strength.

- Thickness of application – Adequate build-up provides better resistance to chemicals and abrasion.

- Maintenance – Regular cleaning and prompt spill management extend coating performance.

- Traffic load – Facilities with high forklift or machinery traffic may need thicker or reinforced systems.

With Nordbak’s experience, flooring systems can be tailored to meet the specific demands of each petrochemical plant, ensuring maximum longevity.

Cost vs. value over time

At first glance, specialised epoxy coatings can seem like a higher upfront investment. But in a petrochemical facility, lifespan is where value is truly measured. A properly applied Nordbak epoxy system that lasts 15 years or more outperforms cheaper coatings that fail in five, delivering far lower lifecycle costs. Reduced downtime, lower maintenance, and fewer resurfacing projects all contribute to the return on investment.

Practical example

Imagine a petrochemical storage facility where hydrochloric acid and caustic soda are regularly handled. Standard epoxy paint was applied years ago, but within five years the floor began blistering and peeling under chemical attack. After resurfacing with Nordbak Acid Grout and Nordwear 5 Acid, the floor not only resists chemical degradation but also withstands the heavy loads of chemical drums and forklifts. The result is a floor expected to last more than a decade without major repairs.

Why Nordbak is trusted in petrochemicals

For over 40 years, Nordbak has supplied protective coatings to industries where chemical resistance is non-negotiable. In petrochemicals, Nordbak coatings are trusted because they combine:

- Proven acid and chemical resistance – against sulphuric, hydrochloric, alkalis, and salts.

- High compressive and abrasion strength – essential for heavy-duty floors.

- Durability under thermal and mechanical stress – tested in demanding plants across industries.

- Local expertise – tailor-made solutions and on-site application support in South Africa.

Building floors that last decades, not years

In petrochemical facilities, epoxy flooring is not just a protective layer—it’s a safeguard against costly downtime, safety risks, and structural damage. With the right system, floors can last 10–20 years, saving money and ensuring compliance with environmental and safety standards.

By choosing Nordbak’s acid- and chemical-resistant epoxy coatings, petrochemical plants gain the confidence that their floors will stand up to decades of demanding service.

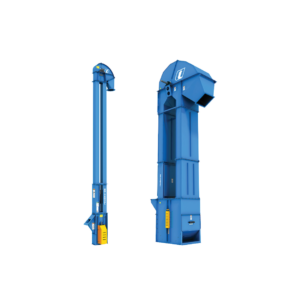

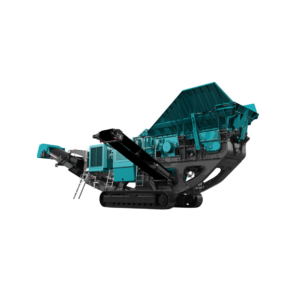

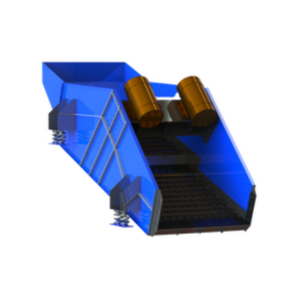

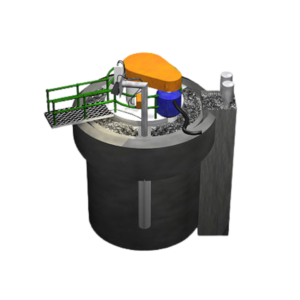

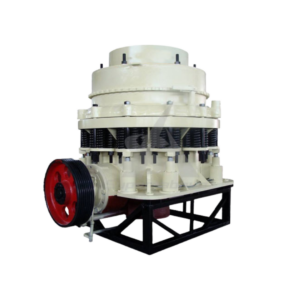

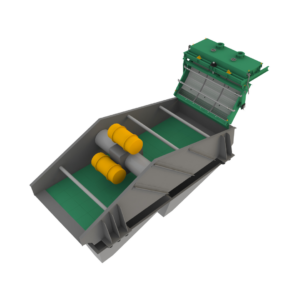

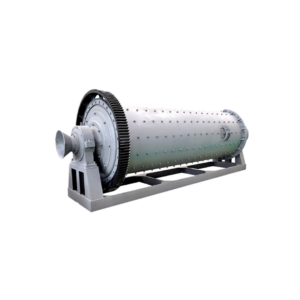

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

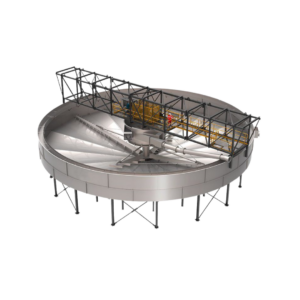

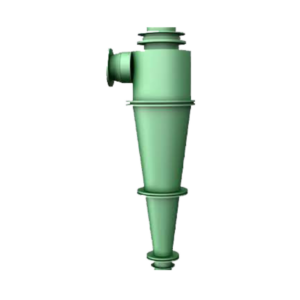

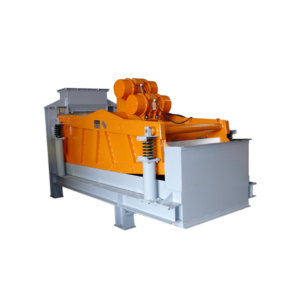

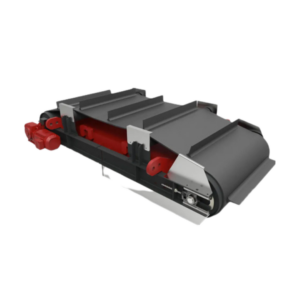

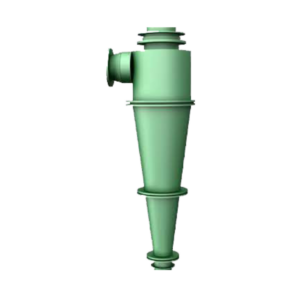

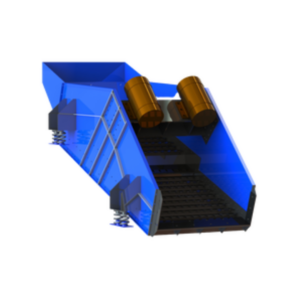

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

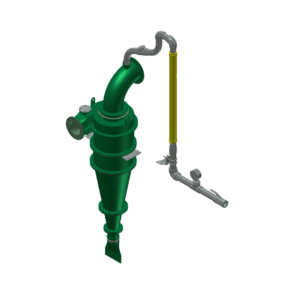

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.