The best epoxy flooring for electroplating facilities is a chemical- and acid-resistant system that can withstand exposure to plating solutions, acids, alkalis, and heavy loads. Nordbak’s range of acid-resistant coatings, including Nordtile®, Nordwear 5 Acid, and Nordbak Acid Grout, provide seamless, non-porous protection against the aggressive chemicals used in electroplating.

Electroplating plants deal with some of the most corrosive environments in manufacturing. Floors are regularly exposed to strong acids, caustics, salts, and electroplating solutions such as chromic acid and sulphates. Without proper protection, uncoated concrete quickly deteriorates – leading to safety hazards, costly downtime, and compliance issues. That’s why epoxy flooring isn’t just recommended; it’s essential.

Why electroplating floors are at risk

Electroplating processes involve constant exposure to highly corrosive substances. Even small drips or mist settling on the floor can damage concrete over time. Some of the biggest risks include:

- Chemical attack from acids like sulphuric, hydrochloric, or chromic acid.

- Alkaline damage from caustic soda and other bases.

- Salt crystallisation which weakens the concrete surface.

- Physical wear from heavy racks, equipment, and foot traffic.

These combined factors make electroplating floors some of the most demanding industrial surfaces to protect.

Epoxy coatings: the first line of defence

Epoxy flooring systems are uniquely suited to this environment. Unlike standard paints or sealers, industrial-grade epoxy coatings form a seamless, impermeable layer that prevents chemicals from penetrating into the concrete substrate. Nordbak’s acid-resistant epoxy systems have been engineered for precisely these kinds of applications, ensuring protection even in immersion conditions.

Products like Nordtile® and Nordwear 5 Acid offer proven resistance to sulphuric acid immersion up to 50%, while maintaining strong abrasion and impact resistance. These qualities make them particularly well suited for plating facilities where floors must endure both chemical and mechanical stresses.

Balancing chemical resistance with durability

A good electroplating floor doesn’t just resist acids – it also needs to stand up to the daily pressures of an industrial facility. Forklifts, heavy metal racks, and constant cleaning demand coatings with high compressive and abrasion strength. Nordbak’s Fixwear and Nordwear 8 compounds provide exactly this combination: resilience against both chemical exposure and physical impact.

By combining chemical-resistant linings with abrasion-resistant compounds, Nordbak creates flooring systems that perform on all fronts – ensuring that protection isn’t compromised by wear and tear.

The hidden costs of unprotected flooring

Electroplating facilities that rely on unprotected or poorly coated concrete often face recurring problems:

- Frequent shutdowns for patch repairs.

- Escalating maintenance budgets.

- Health and safety risks from uneven, corroded surfaces.

- Environmental compliance issues if chemicals penetrate the substrate.

These costs add up quickly, often exceeding the investment in a properly applied epoxy system. In contrast, Nordbak coatings provide long-term durability, reducing both downtime and maintenance.

Practical application example

Consider a facility where chrome plating baths are housed. Even with careful handling, splashes and vapour settle on the surrounding floor area. Over months, the concrete begins to discolour, soften, and pit, creating tripping hazards and requiring frequent patching.

Once the floor is resurfaced with a Nordbak acid-resistant epoxy coating, the difference is immediate. Spills no longer penetrate, the surface remains smooth and safe, and maintenance teams spend less time dealing with flooring issues. The facility gains not only compliance assurance but also operational efficiency.

Why Nordbak solutions stand out

Nordbak has been formulating acid- and chemical-resistant linings for over 40 years, serving industries where failure is not an option. In electroplating, this translates into coatings that are:

- Proven against acids and alkalis – designed for immersion conditions.

- Durable under load – with high compressive and abrasion resistance.

- Seamless and non-porous – preventing hidden seepage and damage.

- Field tested – trusted by mining, petrochemical, and industrial sectors.

Nordbak’s experience and ability to tailor solutions for specific applications make it the reliable choice for electroplating facilities.

Protecting your plating floors for the long term

When it comes to electroplating facilities, epoxy flooring isn’t just a protective measure – it’s a business investment. The right coating ensures safety, compliance, and reduced downtime, while extending the life of the concrete beneath.

With Nordbak’s acid- and abrasion-resistant epoxy systems, you can safeguard your floors against the toughest chemical environments, ensuring your facility stays efficient, compliant, and safe for years to come.

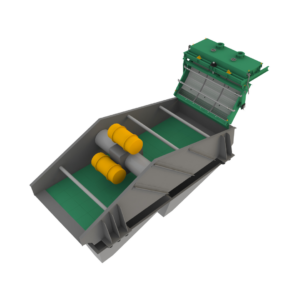

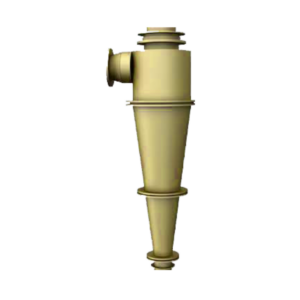

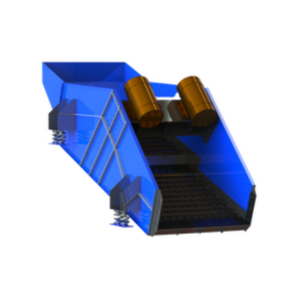

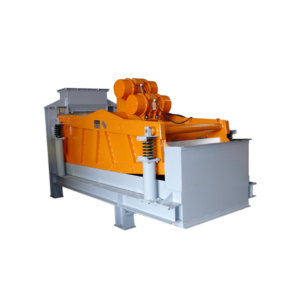

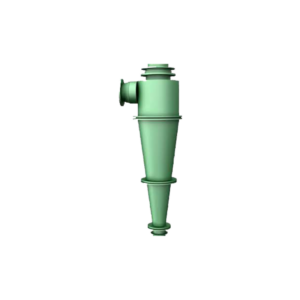

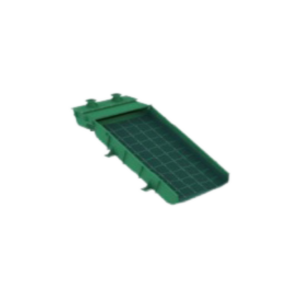

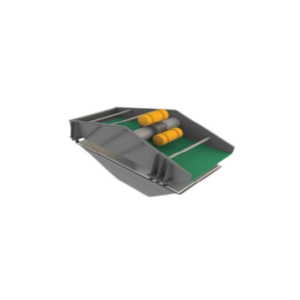

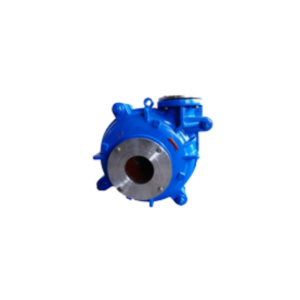

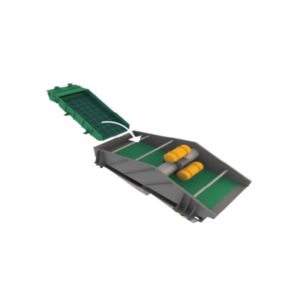

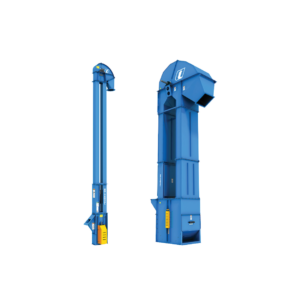

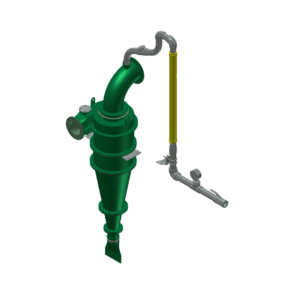

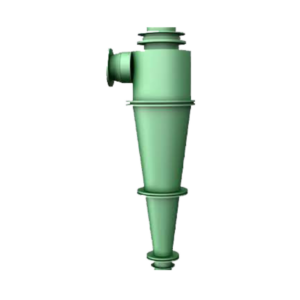

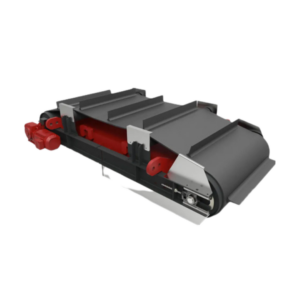

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

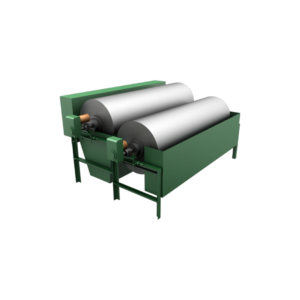

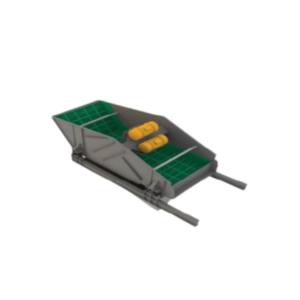

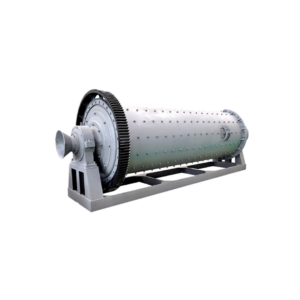

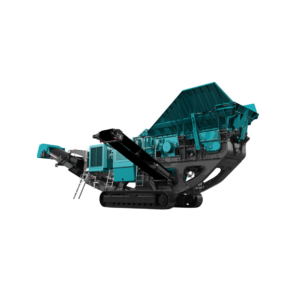

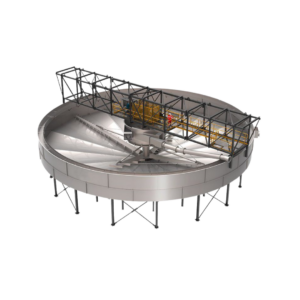

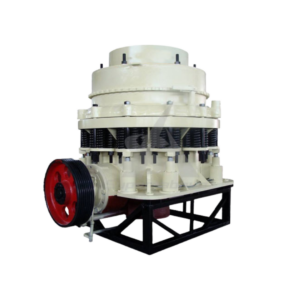

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.