The best way to protect concrete floors in a chemical manufacturing plant is to apply an acid – and chemical-resistant epoxy coating that forms a seamless, non-porous barrier. Nordbak’s range of acid-resistant coatings, grouts, and abrasion-resistant compounds are specifically designed to withstand aggressive chemical attack while extending the lifespan of concrete floors.

Concrete may be tough, but in a chemical plant it faces one of the harshest environments imaginable. Acids, alkalis, solvents, and salts all have the potential to degrade unprotected surfaces. Add in the impact of heavy equipment, constant traffic, and occasional spills, and even the strongest concrete will start showing cracks, pits, and chemical erosion. That’s why protective floor coatings are not optional—they are essential for safety, compliance, and long-term cost savings.

Why concrete floors need more than strength

On its own, concrete is highly porous. Liquids seep in, and over time the chemistry of the floor changes, leading to structural breakdown. In a plant handling chemicals like sulphuric acid, hydrochloric acid, or caustic soda, this can happen surprisingly fast. Once the floor is compromised, you face more than cosmetic issues:

- Safety hazards from uneven, pitted surfaces.

- Chemical exposure risks for workers.

- Compliance issues with environmental and occupational regulations.

- Costly repairs or even full slab replacements.

In short: unprotected concrete is a liability in a chemical environment.

The power of epoxy-based protection

Epoxy coatings solve these problems by sealing concrete under a dense, chemical-resistant layer. Nordbak’s acid-resistant epoxy formulations are designed to perform where standard paints and sealers fail. These coatings bond directly to prepared concrete, creating a seamless, non-porous finish that stops corrosive agents in their tracks.

One key option for manufacturing plants is Nordbak Acid Grout, which resists dilute acid exposure and offers compressive strength far greater than concrete. Similarly, Nordtile® and Nordwear 5 Acid are proven solutions that withstand up to 50% sulphuric acid in immersion, making them ideal for high-risk flooring areas.

These aren’t general-purpose coatings – they’ve been engineered specifically for environments where acids and alkalis are a daily presence.

Standing up to wear and tear

In a chemical plant, chemical resistance alone isn’t enough. Floors must also endure:

- Forklift and trolley traffic.

- Heavy machinery loads.

- Constant cleaning and washdowns.

Nordbak’s protective coatings are designed with abrasion and impact resistance in addition to their chemical resilience. For example, Nordwear 8 and Fixwear are co-polymer systems that combine high compressive strength with resistance to both chemical attack and mechanical wear. This means the floor coating isn’t just a shield against spills – it’s a surface tough enough for daily operations.

Long-term benefits of protective coatings

When a plant invests in chemical-resistant flooring, the payoff comes in several ways:

- Extended lifespan of concrete – Floors last years longer without degradation.

- Reduced downtime – Less need for repairs or resurfacing.

- Lower maintenance costs – Coated surfaces are easier to clean and decontaminate.

- Improved compliance – Meets health, safety, and environmental standards.

- Safer working environment – Smooth, intact floors reduce slip and trip risks.

These benefits explain why industries from mining to petrochemicals have relied on Nordbak coatings for over four decades.

A real-world scenario

Picture a chemical plant that stores and transfers sulphuric acid daily. Despite strict handling procedures, minor splashes reach the floor near tanks and pumps. Within months, bare concrete shows pitting and staining. Cleaning crews struggle, and inspectors raise concerns.

The facility installs a Nordbak acid-resistant coating system. The transformation is immediate: spills can be wiped up, the floor remains intact, and regulatory audits no longer highlight flooring as a risk. Just as important, the plant saves on constant patching and repair work.

Why Nordbak coatings are trusted

Nordbak isn’t new to chemical resistance. For more than 40 years, the company has supplied coatings and linings that protect against acids, alkalis, and corrosion in some of the most demanding industries worldwide. Its products aren’t theoretical – they’ve been field-tested in mines, refineries, cement plants, and chemical factories.

What makes them stand out is the combination of:

- Proven formulations with decades of field success.

- Local expertise in South Africa and beyond.

- Tailor-made solutions available for specialised applications.

- Durability that surpasses traditional coatings and concrete repair methods.

Protecting your plant floor starts here

Protecting concrete floors in a chemical manufacturing plant isn’t about temporary fixes. It’s about applying the right coating system from the start – a system that resists acids, alkalis, and wear while standing up to years of industrial use.

With Nordbak’s range of acid- and abrasion-resistant epoxy coatings, you can turn your plant’s floors from a liability into a long-term asset.

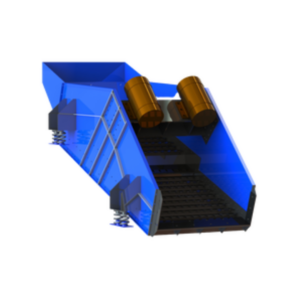

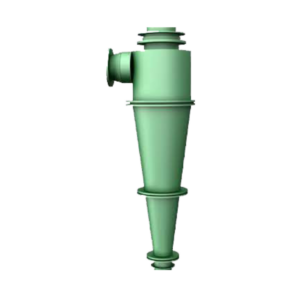

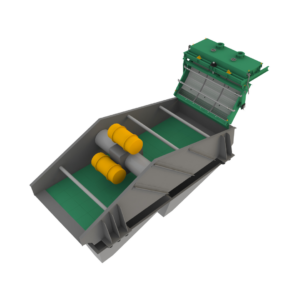

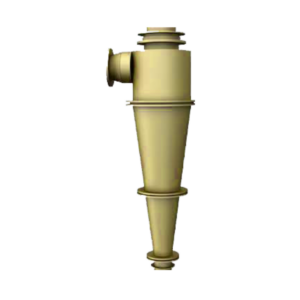

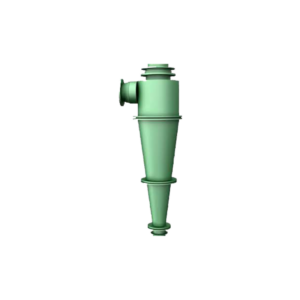

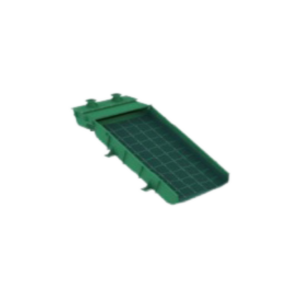

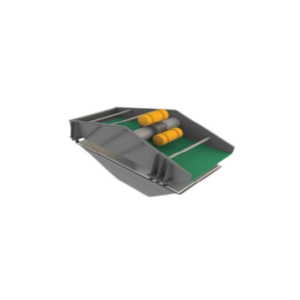

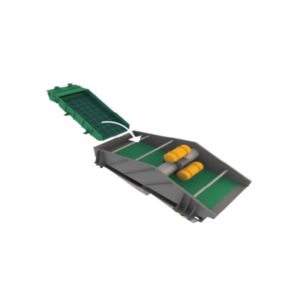

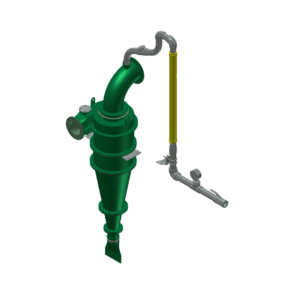

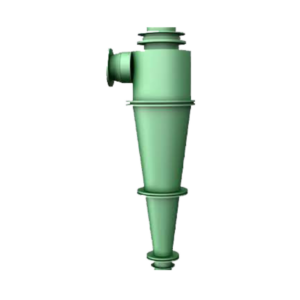

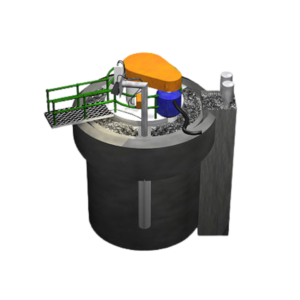

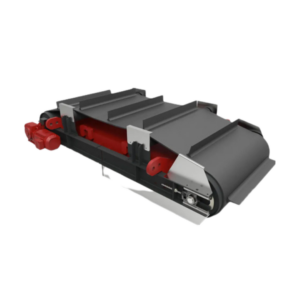

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

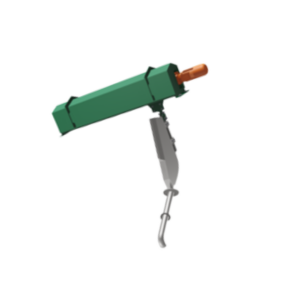

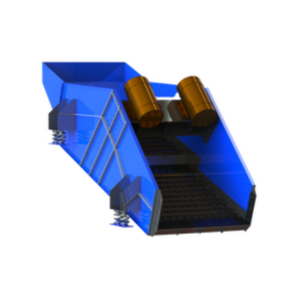

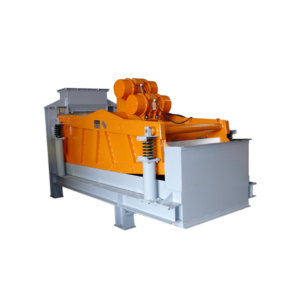

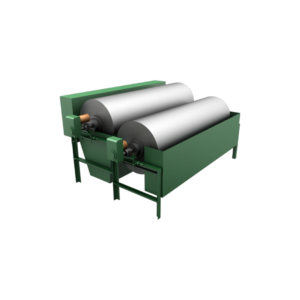

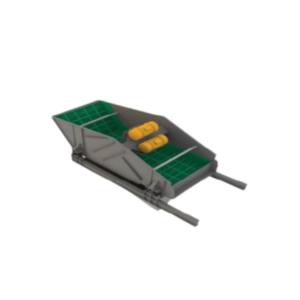

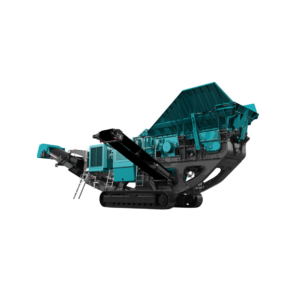

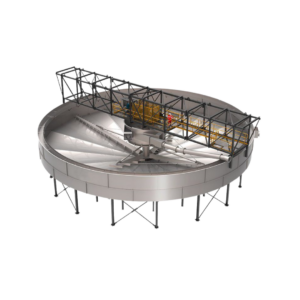

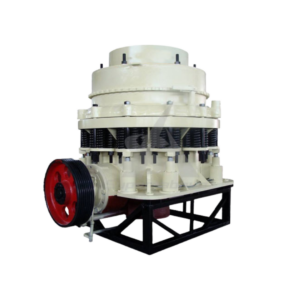

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.