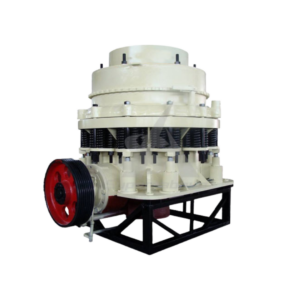

The best material for backing cone and gyratory crushers is a high-strength, epoxy-based compound. These materials deliver superior compressive strength, excellent adhesion, and durability under extreme impact and vibration. They’re also safer and easier to use than molten metal alternatives.

Why Backing Compounds Matter

Crushers in mining environments take a serious beating. Over time, even the most rugged machines develop gaps between liners and frames. If left unaddressed, these voids can lead to poor wear part contact, misalignment, and unplanned shutdowns.

That’s where backing compounds come in: they fill in those gaps, lock everything in place, and absorb the intense forces generated during crushing.

Epoxy: The New Standard

In the past, many operations relied on molten metal backings like zinc or Babbitt.

But those come with a long list of drawbacks:

- Require high-heat equipment and careful handling

- Pose safety risks during application

- Take longer to cool and cure

Epoxy-based compounds have quickly become the industry standard because they solve all of the above. They’re:

- Pourable at room temperature

- Fast-curing

- Safer to store and handle

- Capable of withstanding high impact and vibration

Built for Harsh Conditions

Modern epoxy crusher backing compounds are engineered for strength. Many offer compressive strength ratings upwards of 100 MPa, making them ideal for:

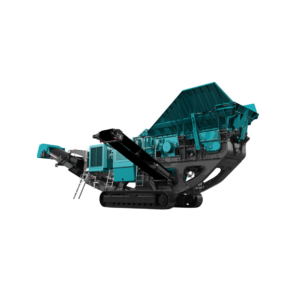

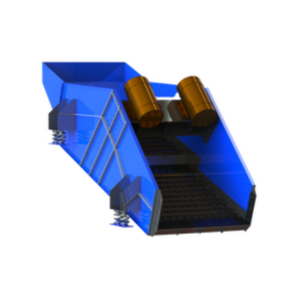

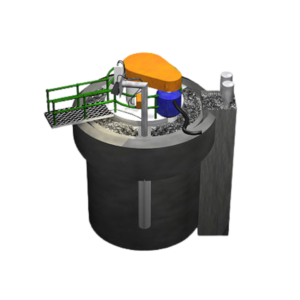

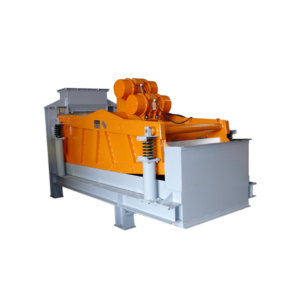

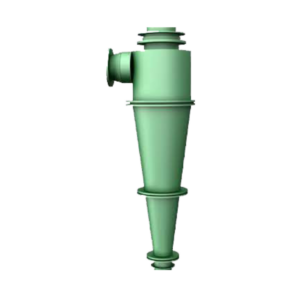

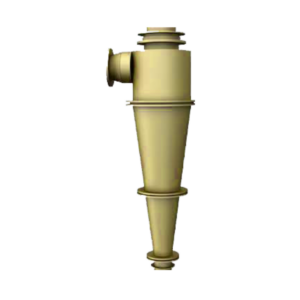

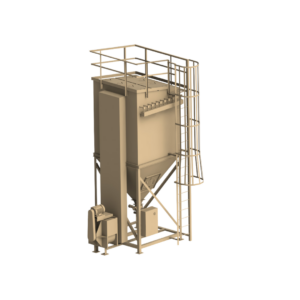

- Cone crushers

- Gyratory crushers

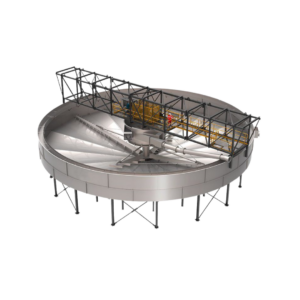

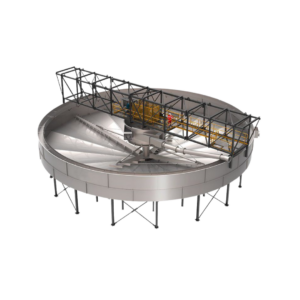

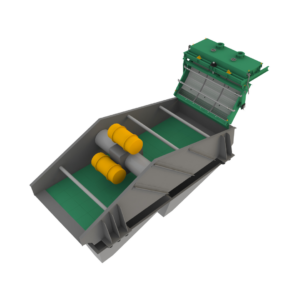

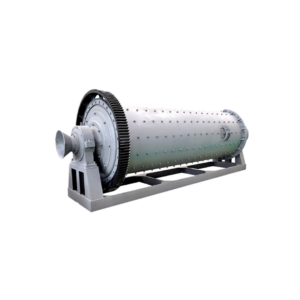

- Mill liners

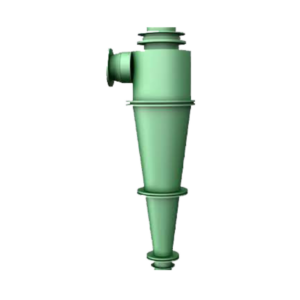

- Pulverizers

Their high volumetric stability ensures no shrinkage or cracking, even under temperature swings and wet conditions – common challenges in open-pit and underground mines.

Choosing the Right Epoxy Backing

Not all epoxy compounds are created equal. You’ll want to consider:

- Ore hardness – harder ores demand higher impact resistance

- Crusher size – larger machines may need higher volume kits

- Downtime constraints – fast-set versions are available for quick turnarounds

There are standard options for general-duty applications, high-impact versions for aggressive loads, and fast-cure variants for time-sensitive maintenance.

Final Thoughts

If you’re operating in mining or aggregate production, epoxy-based crusher backing is a no-brainer. It’s safer, faster, and tougher than old-school metal methods – and it keeps your critical assets performing at their peak.

Back your crushers with the right material, and they’ll return the favour with reliability and longevity.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

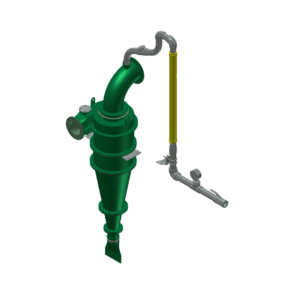

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.